Introduction

Defects due to particles tend to be more serious due to paint-induced particles, dust, fiber scraps, insects, other minute materials and also due to electrostatic adsorption due to static electricity. Therefore, it is necessary to grasp and observe the conditions of the surrounding environment in order to solve these problems.

Paint and paint can

- Inclusion of dust deposited on the top plate of the paint can into the paint.

- The top plate of the paint can was released with a can-cutter, and an agitator blade scraped the inner wall of the paint can.

- The required amount was taken from the hardener can of the two-component urethane paint and some of the hardener cured in the can because the lid was closed without purging nitrogen.

Compounding tanks and their surrounding facilities

- Water condensed in a local exhaust duct connected to a paint supply tank for preparing a two-component urethane paint mixed into the supply tank and reacted with a curing agent (isocyanate) to form particles.

- The coagulated paint remaining on the mesh was dropped and mixed when the paint filtration mesh was replaced.

Paint supply route

- Paint is deposited and cured on the dead space between the ball of the ball valve and the housing in the paint piping. (Selection of a valve without dead space or cleaning in a valve half-open state is recommended)

- Potential difference caused by different metal bonding occurred at the joint part of brass ball valve and the stainless steel piping, and water-based paint agglomerated.

- Paint sedimentation are generated in the piping due to long-term use without cleaning of the paint supply piping. If cleaning is insufficient even after cleaning of the paint piping, the deposited paint particles fall off and discharge. It is necessary to continue thorough cleaning of long-standing deposited paints over several days using powerful paint piping cleaners.

- Paint sedimentation are generated in the dead space (near the entrance and exit) inside the diaphragm pump for feeding paint.

- The water-based paint was washed with water after high-pressure air extrusion, but the water-based paint was not redissolved in water after drying. Brush using water-based paint is immersed in water immediately, and can be reused well by repeating leaving for ten minutes and washing with water."

- At the static mixer for two-part urethane paint, gels and particles are always generated. (Observation)

Painting booths and their surrounding environment

- The spray air used to remove dust causes the resin parts to take more static, resulting in electrostatic adsorption of dust.

- Humidity in the painting booth was not controlled. Painting was carried out under a low humidity atmosphere, and dust was electrostatically adsorbed.

- The dust accumulated on the electrode of the static electricity removal device came off.

- Particles of paint adhering to the top plate of the painting booth drops off due to the howling (periodic vibration) of the painting booth.

- Powdery paint was scattered by the wind blown off toward the gratings and painting jigs, on which paint that easily pulverized adhered and accumulated.

- Dust deposited between the door and the door frame used to enter and exit the paint booth came off.

- The BOX tissue and roll paper were brought into the paint booth and paint preparation room. (Nonwoven fabric with dustproof cut surface is good.)

- Painting with reduced capacity of the exhaust fan in order to suppress foaming of painting booth water, painting mist during painting scattered through the booth.

- The amount of air supplied to the painting booth was small. When the door of the building was opened, dust in the room and from the outside scattered toward the painting booth.

Others

- Mosquitoes that occur in a pool of water, such as a gutter. (Pesticides that prevent flies and mosquitoes from emerging from maggots to feathers are on the market.)

- The insects gathered in the street lighting around the painting room. (It is necessary to use UV cut lighting and UV lighting separately.)

- The electrostatic clothes were dried outdoors in the sun or washed and dried together with the gloves. Therefore, the electrostatic clothes were covered with waste thread and dust.

Reference: Static electricity

An antistatic agent or the like is kneaded in the resin pellets for molding, and the resin pellets are designed so that static electricity is hardly charged when the resin pellets are handled in a molding machine or the like.

Further, carbon, acetylene black, or the like may be kneaded so that the molded article is not charged.

An electrification series is shown as an index of the likelihood of electrostatic charge.

Under an environment of about 60% humidity or less, most resins are charged (-) by friction with air.

The cloth and the resin are charged to (+) or (-) depending on the electrification series of each material.

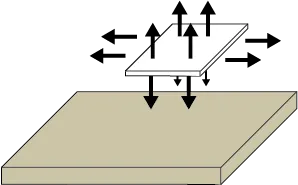

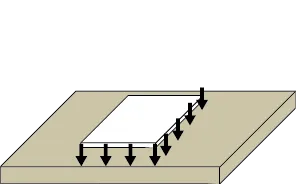

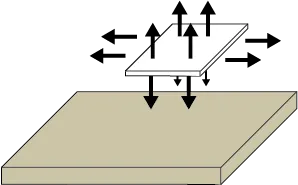

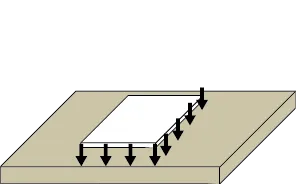

When a resin workpiece having an electrostatic pressure of several kilovolts in the air is placed on an object, the electrostatic pressure decreases to a level close to 0V. A few kV is shown when it is again located in the air. The electric lines of force when the workpiece is in the air are directed in all directions. However, on the object, because the electric lines of force are directed toward the object, the amount of charge is apparently low, and the amount of charge does not change unless the workpiece is neutralized. That is, when the resin workpiece is supported by a metal rod-shaped jig or the like, the electrostatic pressure on the surface of the workpiece is high, and if the static electricity is not removed by the static electricity removing air or the like, the dust or the like is electrostatically adsorbed. On the other hand, when the workpiece is supported by a planar jig, the workpiece becomes to take high electrostatic pressure immediately after the work is removed from the jig, and dust and the like are electrostatically adsorbed. Pay attention when transferring a workpiece from a jig for wiping to that of painting.

It is strongly recommended that you be aware of humidity in winter and that you use an electrostatic potential meter to monitor the charging condition and take measures against static electricity.

Characteristic of statc electricity

|

When an object in the air, line of electric force are directed to all directio and electrostatic voltage become higher according to charged amount. |

|

when an object is placed on the other object, line of electric force are directed to the other object and electrostatic voltage become lower. |

Related articles / products

|

Products information

- Water based dust adsorbent for paint booth, DUSTRON CT-1621U

- KAKEN TECH has developed DUSTRON, a water-soluble adhesive that is applied to booth walls and mesh to collect dust, dirt, and small insects. DUSTRON is a product that does not dry out easily, so there is no need to apply every day! At room temperature, it can retain its adhesive property for six months.

|

|---|

|

Products information

- Anti-static clothing and robot suit cleanser, SUKKIRIN

- KAKEN TECH has developed the SUKKIRIN series of washing agents that remove paint mist, sealer, and oil stains without damaging the base material of electrostatic suits and robot suits.

|

|---|

|

Products information

- Paint remover STRIAL series

- Cured paint remover, STRIAL series is for removing paint adhering to jigs and other tools used in the painting process.

|

|---|

|

Products information

- Wiping agents for degreasing, PLACLEAN series

- It removes contaminants such as mold release agents to reduce cissing, and reduces defects by reducing the amount of static charge after wiping.

|

|---|

|

Products information

- Paint piping cleaner SL-709U

- It removes paint that cannot be removed by the cleaning thinner that is always used to reduce product defects. It can also be used for periodic maintenance of bell cups, paint piping, etc.

|

|---|

Back to List