- Company

- Products

- Technical report

- Indusrial cleaning

- Micro Joining and Assembly Technology

- Ultrasonic technology

- Trouble solution

- Cleaning

- Removing

- Attaching

- PCB Columns

We will exhibit our products at the next JISSO process technology to be held at Tokyo Big Sight from Jun 12 (Wed.), 2024.

We look forward to seeing you at our booth.

| Open period | Jun 12(Wed.) - 14(Fri.), 2024 10:00 - 17:00 |

|

|---|---|---|

| Venue | Tokyo Big Sight [ACCESS] | |

| Booth No | East 4 hall 4C-16 | |

| Admission Registration | Pre-registration for admission is required. | |

| Official URL | https://www.jpcashow.com/show2024/en/ | |

| Highlights | KAKEN TECH contributes to solving troublesome problems that occur on the mounting line with its cleaning, adhesion, and removing technologies! We will exhibit our newly developed flux cleaning system! Please visit our booth to find out the truth about our "high-performance, environmentally friendly cleaning system. In addition, we also introduce cleaning agents with high cleaning performance + α characteristics such as low VOC, non-hazardous materials, and low odor. [Exhibited Products] Stencil cleaners / [NEW]Deflux cleaning system / Reflow oven cleaning / pallet(wave soldering pallets) cleaning / IPA alternative cleaning agent | |

!!Prior admission registration is required!!

Click on the image to open the registration page for admission badges.

Click to catalogue download page

Flux cleaning is indispensable for ensuring the reliability of high-density mounting PCBs. Amidst tightening regulations on chemical substances, such as the discontinuation of CFC substitut.es and the addition of GB standards for cleaning agents to China's VOC regulations, KAKEN TECH has developed the MICROCLEAN ECO & MARKLESS

ECO Series of high-performance, low-VOC cleaning agents that provide both further high-precision cleaning and environmental friendliness |

☝Excellent cleaning performance for narrow gaps and particle removal A new concept of cleaning mechanism enables cleaning of flux in narrow gaps. It also excels in the removal of particles such as minute solder balls, sebum, and fine particles, which are difficult to remove with conventional flux cleaners. |

| ☝Environmentally friendly, low VOC, and non-hazardous Approximately 70% of the components consist of water, which reduces emissions of VOCs (volatile organic compounds) due to the drying process and volatilization. It has no flash point, and does not fall under the United Nations Recommendations on the Transport of Dangerous Goods (UNRTDG), so it can be transported as a normal product during international transportation. |

The Pallet Cleaner PCLT is a system for cleaning flux on pallets (sometimes called carrier pallets, carriers, or Dip pallets) used in the wave soldering process.

The PCLT uses a shower type cleaning system instead of ultrasonic or brush cleaning which may deform the pallet opening.

|

Multi-Pallet Cleaning Flow pallets (carrier pallets and solder pallets) up to 400 mm square can be hold in the machine. |

| Large opening The opening of the PALLETCLEANER is 760 x 440 mm, and the door opens wide for easy loading and unloading of pallets. Also, by removing the stand for pallets, large reflow parts can be cleaned. | |

| Simple liquid exchange When draining liquid, a pail (empty) of PALLETCLEAN, a dedicated cleaning agent, can be simply set in the drain port to drain liquid without soiling hands. | |

| 100V power supply The machine can be started up with only a 100 V power supply, eliminating the need for a 200 V power supply and making it easier to install! | |

| Special price The price is more affordable than conventional pallet cleaners! |

KakenClean series is a water-based cleaning agent for reflow ovens and parts inside the ovens that powerfully removes adhered flux contamination.

In addition to reflow ovens and reflow parts, it can also be used for flux cleaning applications in soldering tank transfer jaws, carrier pallets, and fluxers.

|

Low odor No unpleasant odor, making cleaning opration comfortable and contributing to an improved work environment. |

| High cleaning performance Specially formulated cleaning agent has more than 3 times higher flux dissolving power than IPA, even though it is a water-based cleaning agent. | |

| Spray (atomizing) cleaning Spray bottle is used as package. Simply spray the KakenClean series on the target area and wipe it off with a rag after a few minutes. | |

| Laws and Regulations No flash point and can be transported as non-dangerous goods during international transportation. |

Low odor, non-hazardous materials, high cleaning power! Metal mask cleaning agent HA-series and SAWA Corporation's cleaning equipment SC-AH100-LV will be exhibited as a system.

|

Low VOC Compared to conventional solvent-based cleaning agents, VOC has been reduced by approximately 70%. |

| High cleaning power KAKEN TECH's original composition can remove a wide range of contaminants. | |

| Low odor No unpleasant odor, contributing to improvement of the working environment in the mounting process. |

TK PASTE, a high-performance conductive adhesive using specially shaped silver particles.

Our lineup includes low-temperature process conductive connection and low-cost silver paste with low silver content.

Introducing low-temperature curing and highly reliable conductive adhesives for wearable and mobile applications.

|

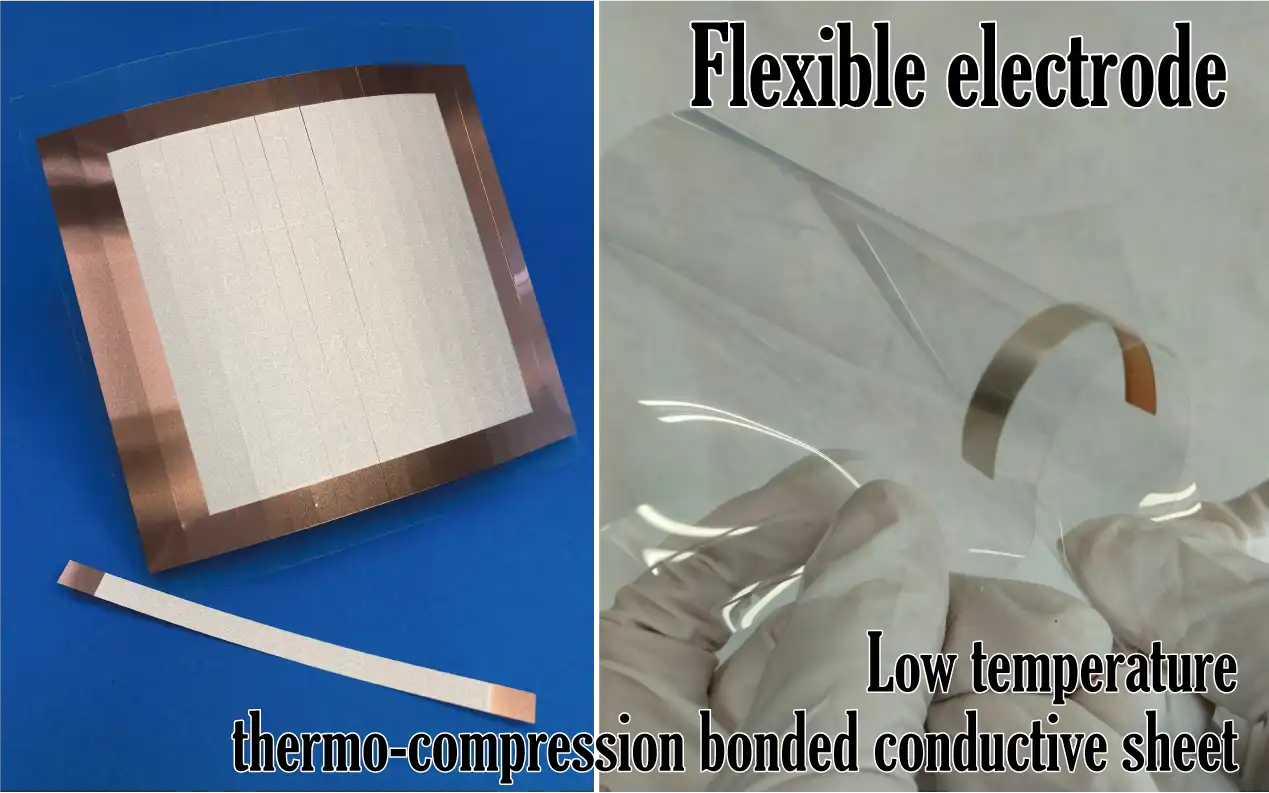

[NEW] Low temperature and thermo-compression bonding conductive silver paste Thermo-compression type conductive adhesive (sheets) developed for conductive bonding with films and resins that are not heat resistant. Ideal for conductive adhesion to PET, polycarbonate, and other materials that cannot be subjected to temperature. |

| [PICK UP] Low temperature and high reliability conductive adhesive TK PASTE CR-5200 The reliability of conductive adhesion has been improved by a special silver powder developed by KAKEN TECH. If you have any problems in bonding components or connecting terminals using conductive adhesives, please contact us. |

MICROCLEANER® and MARKESS® are trademarks of KAKEN TECH CO., LTD. in PRC.

| Inquiry |