- Company

- Products

- Technical report

- Indusrial cleaning

- Micro Joining and Assembly Technology

- Ultrasonic technology

- Trouble solution

- Cleaning

- Removing

- Attaching

- PCB Columns

Published on :

Flux cleaning is the process of removing the flux residue that is generated during the soldering process in the mounting of electronic components.

As we've explained in 『What is flux?』page, flux cleaning is extremely effective in solving and preventing problems caused by flux residue.

I this page, we'll explain why we clean flux, what cleaning methods are available, and what is needed for efficient cleaning.

The purpose and reason for cleaning flux residue is to prevent the occurrence of electrical and physical problems such as the following

|

Degradation of insulation reliability |

|

Corrosion |

|

|

Connection failure |

|

|

Leaks and shorts circuit due to residual solder balls |

|

|

There are other problems such as

, and flux cleaning is an effective way to prevent these kinds of problems from occurring. |

|

When selecting a flux cleaning method, it is necessary to understand not only the cleaning properties of the flux, but also the advantages and disadvantages of the method, such as its impact on the environment, safety, burden on workers (frequent fluid replacement and waste fluid treatment), and running costs.

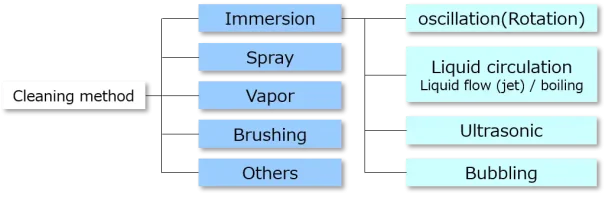

Typical flux cleaning methods are summarized in the figures below.

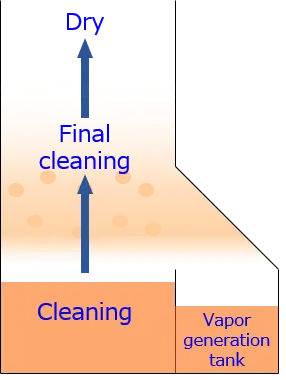

Example of system

| Cleaning | Alternative CFC and brominated cleaning agents |

|---|---|

| Rinse | Clean detergent vapor |

| Dry | Drying naturally |

It has been used in many degreasing applications and eutectic solder flux cleaning, but its solubility in Pb-free solder flux is low. The cleaning agent has no flash point and is very safe, and can be used in the same facilities as CFCs. Because of its high volatility, it tends to cause a lot of volatilization loss, resulting in higher running costs. In addition, the impact of the cleaning agent on the human body and the environment (global warming) has been reported.

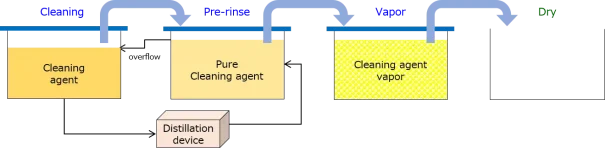

Example of system

| Cleaning | Hydrocarbon-based cleaning agents |

|---|---|

| Rinse | Clean cleaning agent or cleaning agent vapor |

| Dry | Use a combination of decompression and vacuum. |

Explosion proofing of equipment is required and cleaning agents are often used above their flash point. Hydrocarbon-based cleaning agents have high solubility in resin components such as rosin in flux, but they do not remove ionic contamination very well, so contamination may remain. Also, because of the strong attack on the resin, it is necessary to check the effect of the cleaning agent on the parts.

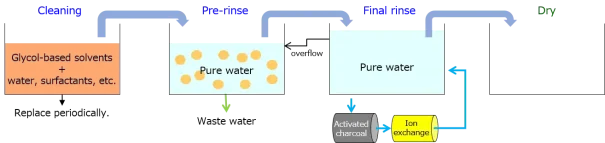

Example of system

| Cleaning | A cleaning agent made by adding a surfactant and water to a solvent such as glycol ether. |

|---|---|

| Rinse | Pure water (highly purified in a water treatment facility). |

| Dry | Hot air drying. Drying properties are much lower than IPA. |

Both cleaning and rinsing agents have no flash point and are very safe. However, since water is contained in the cleaning agent, the cleaning agent may require moisture control. In addition, if the composition of the cleaning agent breaks down due to increased contamination, the contamination may reattach. In addition, since a lot of wastewater is generated, a wastewater treatment facility is required.

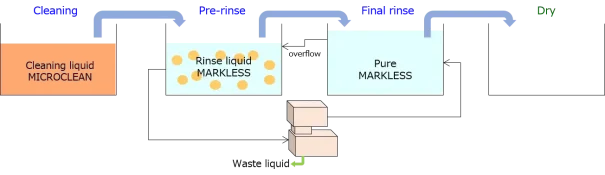

| Cleaning | Glycol ether-based (high boiling point) cleaning agents |

|---|---|

| Rinse | Water contained alcohol |

| Dry | Drying properties equivalent to IPA |

Closed system with no wastewater. The rinse agent, water-containing alcohol " MARKLESS®," is continuously recycled in a built-in distiller. Since no water is used for rinsing, there is no drainage and no need for wastewater treatment facilities.

In addition to the dissolving power of the cleaning solution, the cleaning efficiency can be improved by applying physical force. Most of the current flux cleaning systems use one of the following methods.

A method in which the cleaning workpiece is immersed in a cleaning agent and the flux is removed by the dissolving power of the cleaning agent. Simply immersing the workpiece in the cleaning agent does not diffuse the dissolved flux, so it is often used in conjunction with physical force, such as the following

A method in which a cleaning agent circulated by a pump or similar device is sprayed onto a workpiece immersed in the liquid. Relatively uniform results can be obtained throughout the cleaning tank. The turbulent flow effect can be used to promote diffusion more effectively.

A method of removing contaminants through cavitation and acceleration by propagating ultrasonic waves through the cleaning solution. It is very effective for removing solder balls. Some cleaning workpieces may be damaged by ultrasonic waves, but by adjusting the frequency and output power, flux removability can be improved while minimizing damage.

A method of cleaning in which the cleaning agent is sprayed onto the workpiece like a shower.

The advantages of this system are that it can be used with most cleaning agents* and that flux removal can be improved by increasing the injection pressure.There are some disadvantages: for highly volatile cleaning agents, measures such as sealing the equipment are necessary; increasing the injection pressure has a large impact on the cleaned workpiece; the cleaning agent is misted, leading to volatilization loss; and cleaning performance is poor in areas not exposed to the shower.

* We do not recommend the use of cleaning agents with low flash point or those classified as hazardous materials.

A cleaning method in which the cleaning agent vapor is liquefied (condensation) on the workpiece, and the liquefied cleaning agent flows down while dissolving the flux on the workpiece surface.

This cleaning method is used with chlorinated (trichloroethylene, methylene chloride, etc.), fluorinated (HFE, HFC, etc.), silicon, brominated solvents, and alcohols. It can also be used with hydrocarbon-based cleaners in a vacuum environment.

Cleaning method of scrubbing the surface of a workpiece. A cleaning method in which the surface of the workpiece is physically scrubbed with a brush or pad to remove dirt.

Although the physical force is extremely high, there are concerns about damage to the surface of the substrate and recontamination by fallen fibers and shavings. Areas where physical contact is not possible, such as fine areas and under parts, cannot be cleaned.

Standard Micro Soldering Technology, 3rd Edition

Japan Welding Engineering Society, Micro Soldering Education Committee [ed.]

Nikkan Kogyo Shimbun

|

PCB Mounting Columns

|

|---|---|

|

Trouble solution

|

|

Technial report

|

|

Products information

|

MARKESS® is a trademark of KAKEN TECH CO., LTD. in PRC.

| Inquiry |