- Company

- Products

- Technical report

- Indusrial cleaning

- Micro Joining and Assembly Technology

- Ultrasonic technology

- Trouble solution

- Cleaning

- Removing

- Attaching

- PCB Columns

Published on :

In the reflow process of electronics packaging, solder is supplied to the printed circuit board, electronic components are mounted on the board, and the board is heated and melted in a reflow oven for joining. There are several methods of supplying solder, including supplying solder paste (solder paste) using a metal mask(stencils) or dispenser, precoating (plating), and supplying solder balls (solder balls). The method of printing solder paste using a metal mask is the most commonly used.

In this page, we will explain how to print out solder paste using a metal mask.

There are two main types of stencil used in SMT process.

| Mesh screen mask (mesh plate, screen plate) | Mask with openings formed by emulsion on a base woven with synthetic or metal fibers |

|---|---|

| Metal mask (stencil) | A mask consisting of a metal plate with apertures or the like attached to a frame |

Metal stencil with high printing accuracy is generally used for solder paste printing in the SMT process.

Mesh screen mask |

Metal stencils |

Stainless steel (SUS), nickel, phosphor bronze, and copper are commonly used as materials for metal stencils.

|

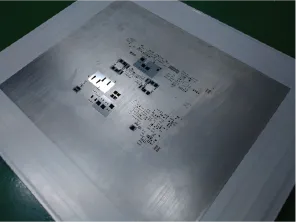

In the SMTprocess, solder paste is often printed using a printing machine like the one shown in the photo on the left. We will show you what mechanism is used to print solder paste. |

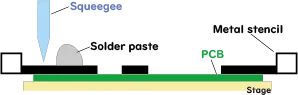

| Set the PCB under the metal stencil. |

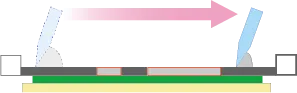

| The squeegee is moved while pressing (pressurizing) downward to apply solder paste through the aperture of the metal stencil to the specified area. |

| Release the set PCB. Solder paste with the same shape as the opening is now printed on the PCB. |

In the SMT process, it is important to be able to print solder paste stably without chipping or overprinting.

Here are some examples of events that can be cited as printing defects.

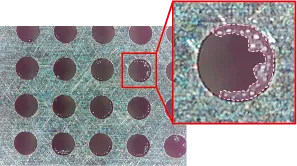

One of the requirements for a metal mask is that the aperture wall must be smooth to prevent solder paste from adhering to the mask and to provide excellent continuous printability. However, when the aperture of the metal mask becomes smaller with finer patterns, the printed solder paste does not transfer to the PCB and may remain in the aperture as shown in the image on the right. The lightly colored area in the image is the solder paste remaining in the aperture. If printing is repeated in this condition, solder paste is printed with a portion of the aperture missing, and the amount of solder supplied is reduced, resulting in a "blurring" problem. |

|

If there is a gap between the mask and the electrode area of the PCB, or if the squeegee is pressed too hard, solder paste will bleed into the periphery of the aperture. The problem is called "bleeding" that the bleeding area is transferred to the PCB. Bleeding can cause soldering defects such as bridging (short-circuiting).

This is where regular metal stencil cleaning becomes important.

To prevent the occurrence of the above problems, metal stencils must be cleaned periodically. When selecting a cleaning agent for metal mask cleaning, there are a wide range of items to focus on.

Here are some of the points to consider when selecting a metal stencil cleaning agent.

In many factories, metal masks are cleaned by hand with IPA (isopropyl alcohol) using a brush or rag.

However, as the mask aperture becomes finer and narrower, solder paste will remain in the aperture even when cleaned with a low solubility cleaning agent such as IPA.Therefore, cleaning agents with high solubility to solder paste (such as glycol ether-based cleaning agents) must be used.

The metal mask consists of a metal plate with an aperture, a metal frame such as aluminum, and a combination, each of which is taped and fixed in place.It is necessary to select a cleaning agent that has minimal effect on the combination, metal frame, and fixing tape, while ensuring solubility to the solder paste.

For example, if a cleaning agent penetrates the fixing tape and decreases the adhesive strength, the tension of the metal mask will decrease, which may cause problems such as printing defects or plate peeling.

As much as the impact on the component, the impact on the environment and human health must also be considered.It is necessary to select a product that contains a low amount of VOCs (volatile organic compounds), does not deplete the ozone layer or cause marine pollution, and for workers, one that causes little skin irritation or odor.

Various notifications and controls may be required when using cleaning agents that fall under laws and regulations.

For example, IPA is frequently used in the mounting process, but in Japan it requires the installation of local exhaust ventilation equipment, which imposes a significant cost burden outside of cleaning.

Therefore, it is necessary to take safety measures and bear the cost, such as wearing work clothes and shoes with antistatic measures when storing and handling the IPA, and using explosion-proof equipment when using IPA in ultrasonic washing machines and other cleaning equipment.When selecting a cleaning agent, it is necessary to check the applicability of various laws and regulations and select a safer cleaning agent in consideration of the worker's work environment.

Standard Micro Soldering Technology, 3rd Edition

Japan Welding Engineering Society, Micro Soldering Education Committee [ed.]

Nikkan Kogyo Shimbun

|

Technial report

|

|---|---|

|

Trouble solution

|

|

Products information

|

KAKEN TECH, MICROCLEANER, MICROCLEAN&MARKLESS and MARKLESS are trademarks of KAKEN TECH CO., LTD. in PRC.

KAKEN TECH is a trademark of KAKEN TECH CO., LTD. in the U.S..

| Inquiry |