- Company

- Products

- Technical report

- Indusrial cleaning

- Micro Joining and Assembly Technology

- Ultrasonic technology

- Trouble solution

- Cleaning

- Removing

- Attaching

- PCB Columns

Published on :

Conductive adhesives, as their name implies, are adhesives through which electricity flows. Also called silver paste, conductive glue or silver glue.

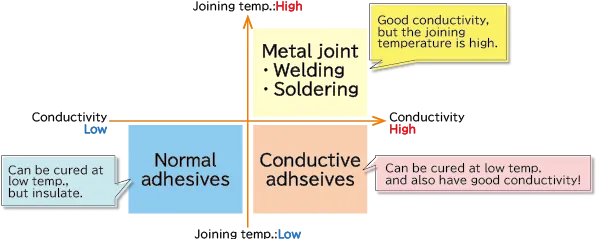

What is different from common adhesives and glues or the solder used for bonding electronic components? The relationship between the bonding temperature and the electrical conductivity will be summarized below.

Metal joints, such as welding and soldering, have good electrical conductivity, but the joining temperature is high.

Normal adhesives can be bonded at low temperatures, but they do not conduct electricity because they are not electrically conductive (insulated).

There's what comes out there: Conductive adhesives! Conductive adhesives can be joined at low temperatures and also have good conductivity! Combines advantages of metal bonding with as of general adhesives.

Until now, solder has been mainly used for conductive bonding of electronic components. However, with the miniaturization of electronic devices and the diversification of wearable devices, the number of cases in which resin parts and film-like members are used is increasing.

Many parts using resin or film have low heat resistance, and are damaged by soldering heating. Therefore, there is an increasing need for conductive bonding materials that replace solder as a means of conducting bonding at low temperatures.

Conductive adhesives are materials that can conduct conductive bonding at lower temperatures than solder. Due to the above background, application examples have been rapidly expanding in recent years.

The processes and characteristics used differ from those of solder, which is a typical conductive bonding material.

Let's look at the advantages and disadvantages of conductive adhesives.

| Benefits of conductive adhesive |

Conductive adhesives ...

|

|---|---|

| Demerits of conductive adhesive |

|

For example, conductive adhesives rather than solder are suitable for joining resin parts and other materials with low heat resistance.

*1 : The movement of the mounted component to be soldered is naturally positioned during the time until the solder melts and solidifies is called the "self-alignment effect." (Reference: MiSUMi-VONA Technical Info)

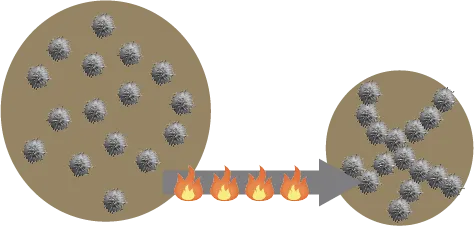

| The main component of normal adhesives is the resin of the insulator, and electrical conduction is impossible. Conductive adhesives are prepared by dispersing conductive particles (also called fillers) in organic binder resins such as epoxy adhesives. Electricity flows when conductive particles come into contact with each other when the adhesive hardens. |

Conductive particles contact each other due to shrinkage during curing of the binder resin, and electricity flows. |

| Unlike solder, in which the metal melts into an alloy, conductive particles in the conductive adhesive does not melt and fuse in this conduction mechanism. Therefore, to ensure good conductivity, it is necessary to contain a certain amount or more of conductive particles in order for the conductive particles to contact each other to form a network. |

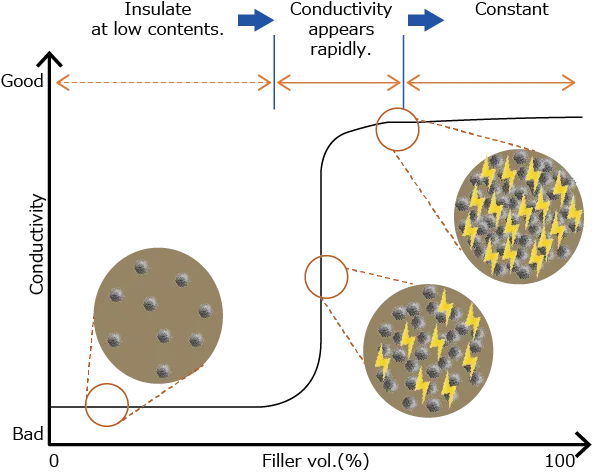

| The graph below shows the relationship between the amount of conductive particles (silver powder) added and the electrical conductivity. If the amount of conductive particles added is small, there is no conduction, but conductivity appears suddenly when added amount exceed a certain amount. |

Conductive adhesives are thought to pass electricity through contact between conductive particles. As the amount of conductive particles increases gradually, conductivity appears suddenly from a certain amount. However, even if more conductive particles are added, the conductivity will not change from a certain amount. [1] [1] Nishikawa, "Conductive Fillers and Conductivity of Conductive Adhesives," Journal of the Society of Smart Processing, Vol. 1, No. 3, pp.138-142,2012 |

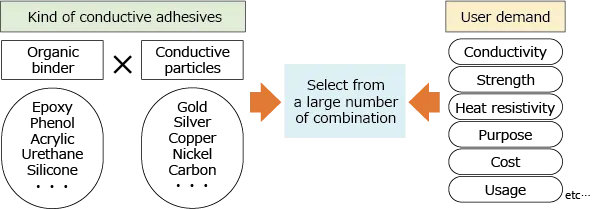

| There are many kinds of organic binders as adhesives and conductive particles to be blended, and so many conductive adhesives are developed and sold on the market. The user should select a conductive adhesive in consideration of performance, application, cost, usage, etc. | |

| For the connection of electronic components, epoxy-based conductive adhesives which use epoxy-based binders and conductive particles of silver and cured by heating, are mainly used for. Epoxy adhesives have excellent properties such as good adhesion to metals, high heat resistance, and low volume shrinkage during curing. Silver is also widely used in electronic materials because of its stable electric conductivity, good electrical conductivity, resistance to oxidation, good storage stability, and high thermal conductivity. | |

| Spherical or flake-like silver conductive particles are commonly used for conductive adhesives, and the size and amount of particles to be blended are determined by the performance. For this reason, conductive adhesives are also called "silver pastes." | |

There are many types of organic binders for adhesive components and conductive particles for electrical conductivity, and so many conductive adhesives have been developed. | |

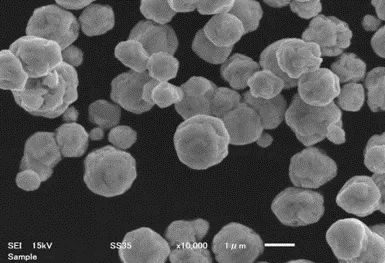

a) Spherical shape |

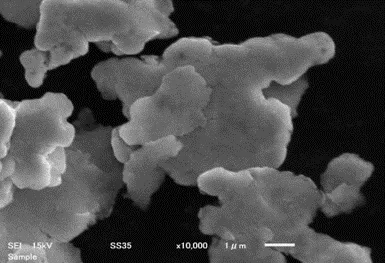

b) Flake shape |

Conductive adhesives for electronic components are mostly made of epoxy resin and silver conductive particles, and silver conductive particles are made of spherical, flake, or other shapes. | |

|

Trouble solution

|

|---|---|

|

Trouble solution

|

|

Products information

|

The content on this page is based on our views and does not describe or define all technologies or products.

The information on this page is the content as of September 2021.

KAKEN TECH, MICROCLEANER, MICROCLEAN&MARKLESS and MARKLESS are trademarks of KAKEN TECH CO., LTD. in PRC.

KAKEN TECH is a trademark of KAKEN TECH CO., LTD. in the U.S..

| Inquiry |