- Company

- Products

- Technical report

- Indusrial cleaning

- Micro Joining and Assembly Technology

- Ultrasonic technology

- Trouble solution

- Cleaning

- Removing

- Attaching

- PCB Columns

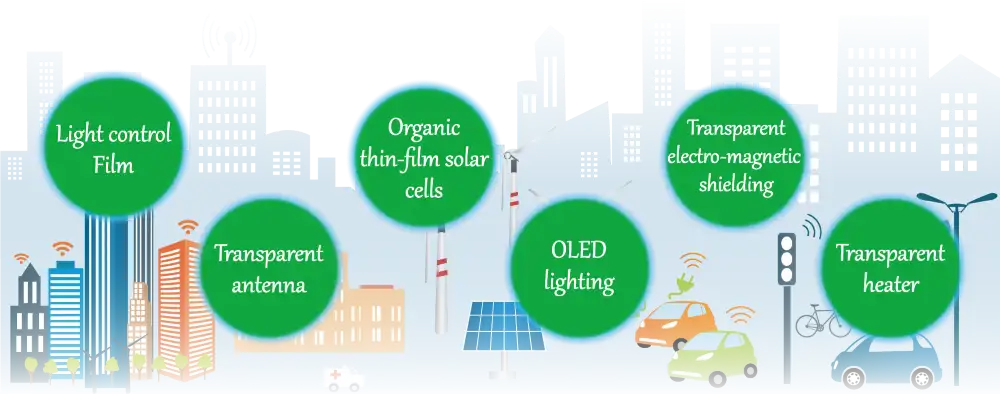

New green technologies are being created every day to save energy and utilize renewable energy for the realization of a sustainable society. One such technology is the development of film devices.

Demand for lightweight, thin, and flexible transparent film devices is expected to continue to grow.

Transparent conductive films used in film devices are generally made by adding conductivity to the surface of PET film, but while they are thin and light, they are extremely weak against heat.

"Soldering" is used for conductive connections in electronic circuits, but solder, which requires high temperatures, cannot be used to connect to film devices on which solar cells and heaters are formed. Anisotropic conductive films (ACF) and conductive adhesives are sometimes used in place of soldering, but each has its own disadvantages and technical challenges that prevent the film device from fully functioning.

A comparison of the new adhesive TKS-030 developed by KAKEN TECH and the conventional method is shown below.

| TK PASTE Thermo-compression type | Conductive adhesive (Thermosetting) | Anisotropic conductive Film (ACF) | Soldering | Grommet | |

|---|---|---|---|---|---|

| Deformation by heat | ○ | △~○ | × | × | ○ |

| Flexibility | ○ | × | △ | × | × |

| Condctivity | ○ | ○ | △ | - | △ |

| Thinness | ○ | ○ | ○ | × | × |

| Number of Processes | ○ | × | △~○ | △ | △ |

| Features | Ideal for electrode take-out of conductive films | Inflexible, causing cracking and warping | Requires high temp. heating High resistance | Cannot be used for films due to high temperatures | No flexibility Cannot be made thin |

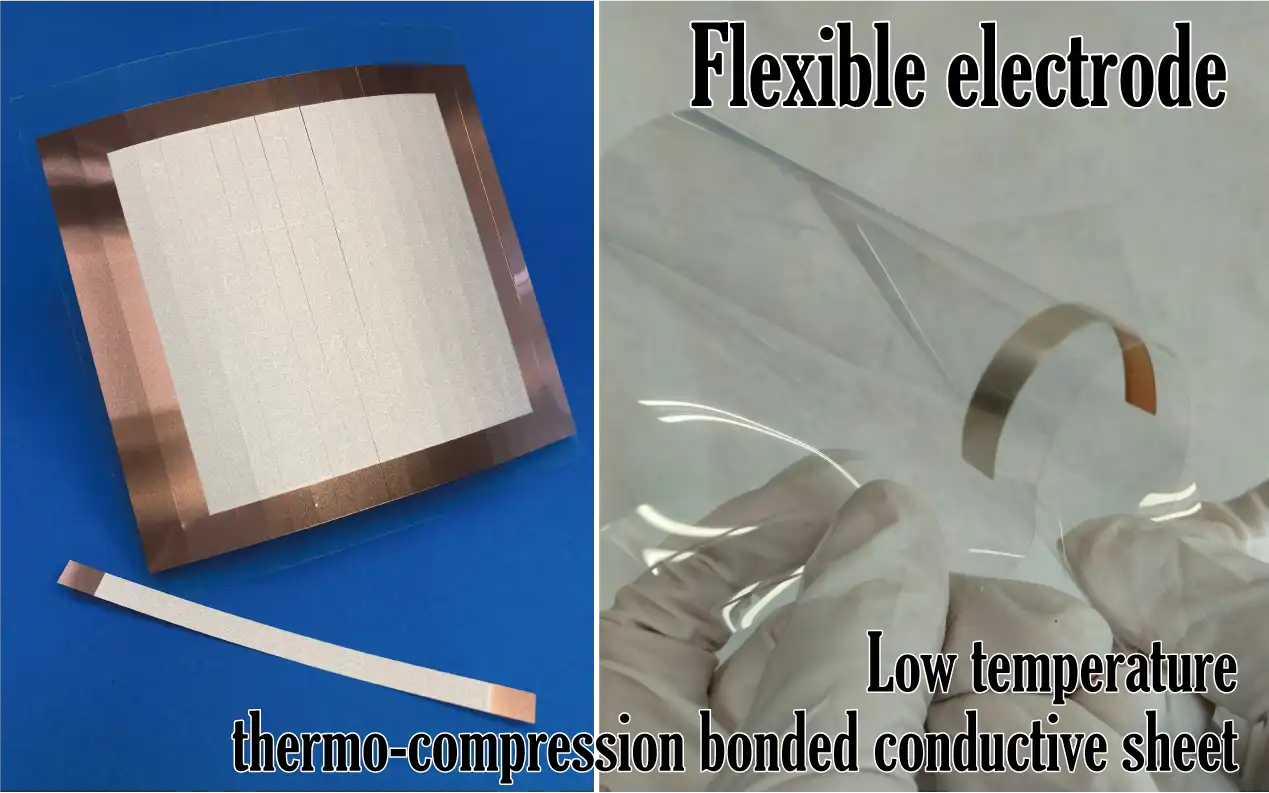

Conventional methods all have their challenges and do not bring out the best of film devices. TKS-030, which can be bonded by low-temperature thermo-compression, is the best method to take out electrodes from thin and flexible transparent conductive films.

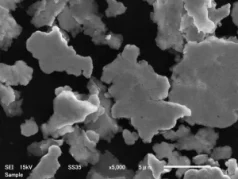

The deciding factor is the shape of the silver!

KAKEN TECH develops unique conductive adhesives using silver powder of various shapes.

TKS-030 developed this time also uses silver powder of the most suitable shape for film devices.

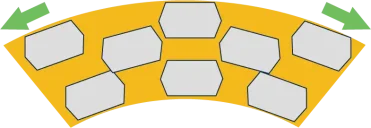

| 【Conventional conductive adhesives】 Conductive adhesives applied to films are stretched to the left and right when they are bent. Inside the conductive adhesive, silver powders become separated from each other, resulting in increased resistance and reduced conductivity. | ||

|

|

|

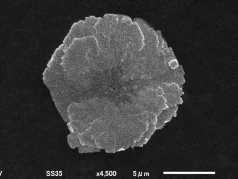

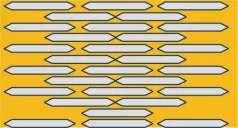

| 【TKS-030】 KAKEN TECH has developed a special silver powder that is large and thin in order to achieve both flexibility and stable conductivity. By blending this powder, we were able to develop a conductive adhesive that does not easily lose conductivity even when bent. | ||

|

|

|

Conductive connection of transparent film devices

・For energy field: Organic thin-film solar cells (e.g. Pebroscite)

・For automatic driving: Transparent heaters (to prevent fogging of cameras), transparent antennas (for vehicle-to-vehicle and road-to-vehicle communications)

・For electric vehicles: light control film (electronic light control window)

Available in screen-printable paste type and pre-printed sheet type

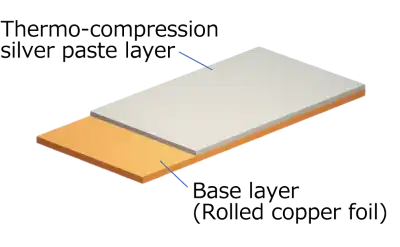

| Low temp. thermo-compression bonding conductive adhesive TK PASTE TKS-030 | ||

| Properties | Paste type | Sheet type |

| Main components | Silver, thermoplastic resin | |

| Base layer | - | Rolled copper foil (C1020 50um) |

| Printed area size | - | 75mm×75mm (Precut:5mm or 3mm width) |

| Paste application method | Screen printing | - |

| Paste drying conditions | 60℃×40min~100℃×20min | - |

| Pressure bonding conditions | 100~120℃/60~120sec/0.5~2.0MPa | |

| Specific resistivity | 2×10-4Ω・cm | |

| Storage condition | Freezing (-10°C or below) | Room temperature |

| ||

|  |  |

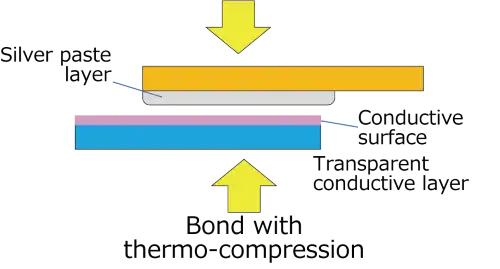

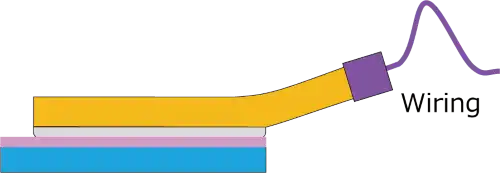

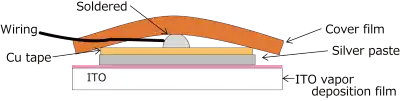

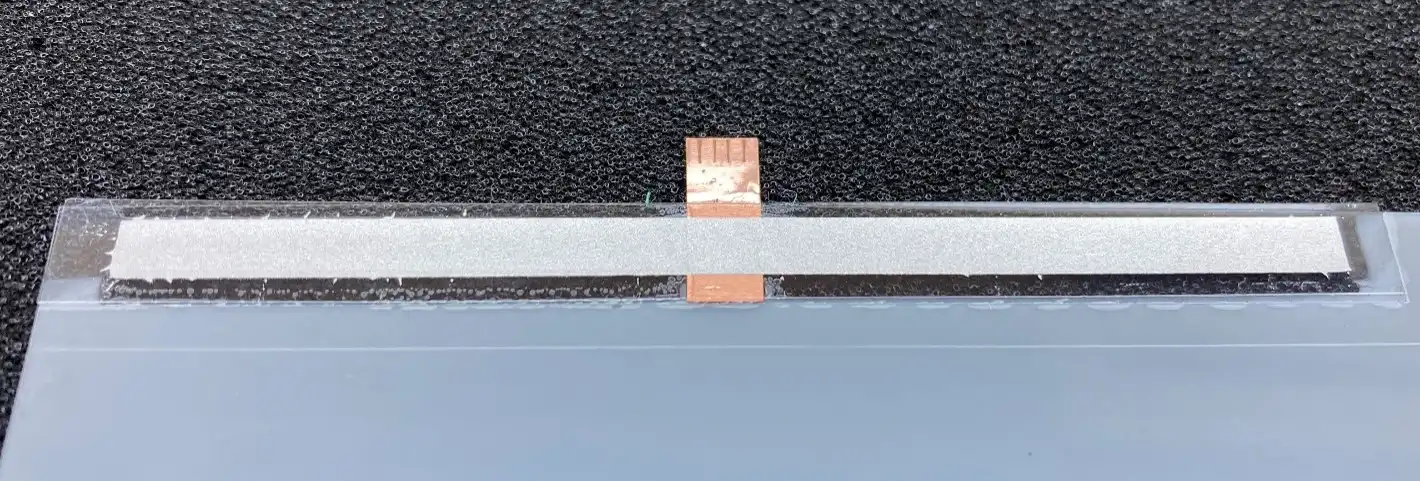

| Problem:In the conventional method, the resistance of the copper tape and ITO surface for soldering is high, so silver paste is used together. Also, the wiring part became thicker due to the use of solder. |

|

| Using TKS-030:Electrode terminals for wiring can be thermo-compression bonded directly to ITO. The thickness has been smartly reduced to less than half, and the process has been significantly shortened. |

|

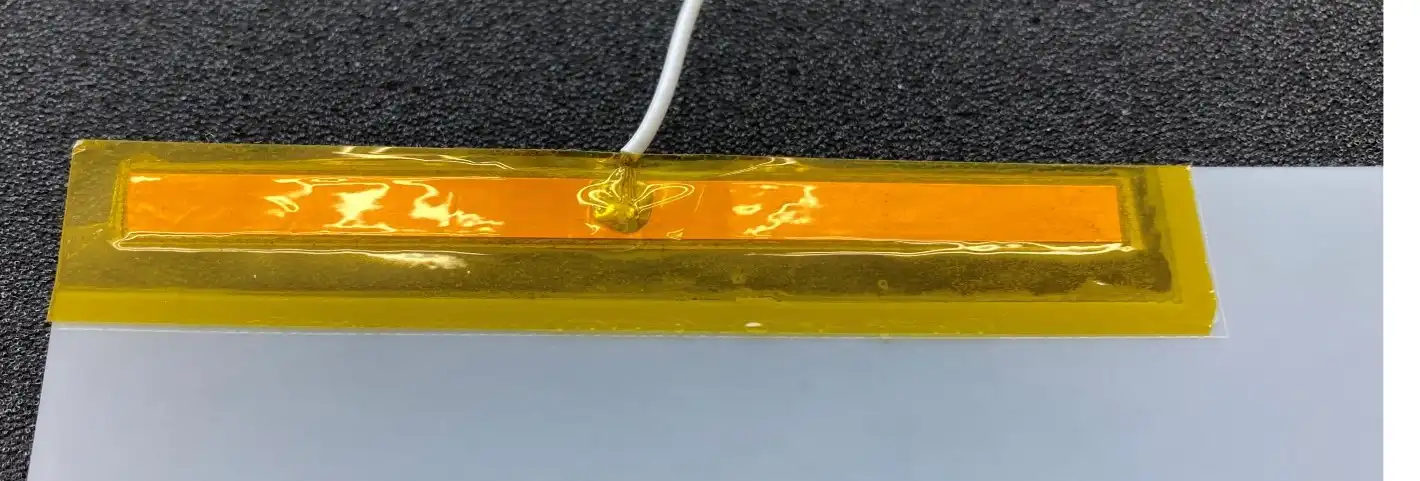

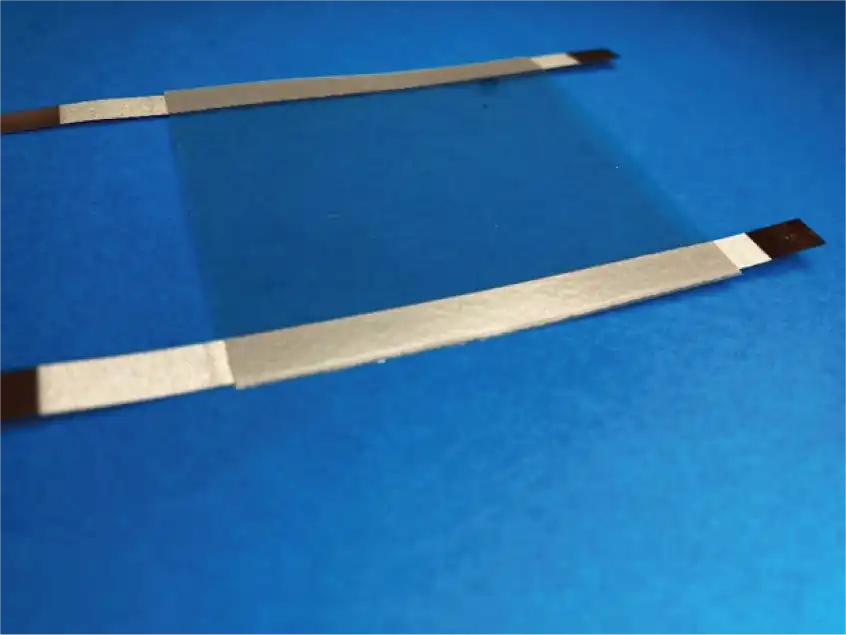

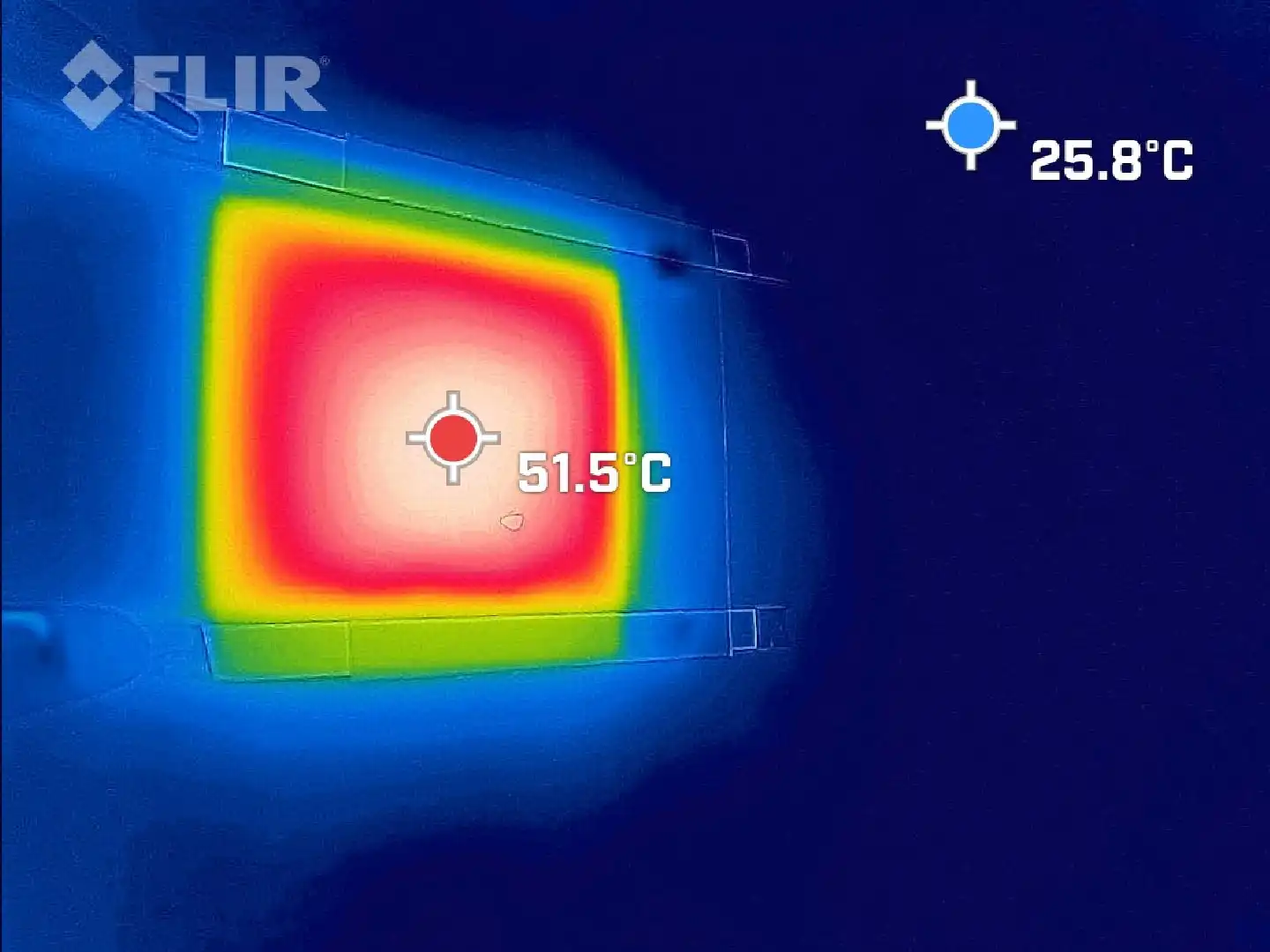

| Problem:Wiring is formed on transparent conductive film with silver paste, etc., and bonded to electrodes with ACF. Stable conductivity could not be obtained due to high resistance and localized heat generation. | ||

| Using TKS-030:TKS-030 thermo-compression bonding sheet (copper foil type) is thermo-compressed directly onto transparent conductive film. When DC current is applied, heat is generated, and it was confirmed that there is no localized heat generation. | ||

Directly thermo-compress the TKS-030 thermo-compression bonding sheet. |

When electric current is applied, heat is generated. No localized heat generation. | |

| Problem:Conductive adhesion to electrodes formed on film substrates using ACF or conductive tape. The resistance of the bonded area is high, and lowering the resistance is an issue. |

| Using TKS-030:Investigated the use of TKS-030 thermo-compression bonding sheet (copper foil type) for bonding electrodes of organic thin-film solar cells formed on film substrates. Low resistance and stable characteristics have been obtained and are under development for practical use. |

| Inquiry |