- Company

- Products

- Technical report

- Indusrial cleaning

- Micro Joining and Assembly Technology

- Ultrasonic technology

- Trouble solution

- Cleaning

- Removing

- Attaching

- PCB Columns

Published on :

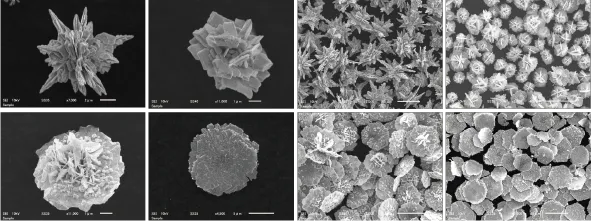

As explained in "What are conductive adhesives?", spherical or flake silver powder is commonly used for conductive adhesive.

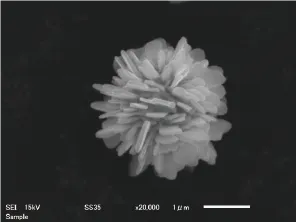

| KAKEN TECH has developed silver powder with a complex shape that is neither spherical nor flaky, and mass-produces it as "TK silver powder". It is known that the conductivity and physical properties of conductive adhesives change depending on the shape of the conductive particles, and we are using this TK silver powder to develop conductive adhesives with unprecedented functions. |

|

| Conductive adhesives that use silver have low resistance and stable conductivity, but their biggest disadvantage is that they are expensive because they use precious metals. |

| KAKEN TECH has developed a low-silver concentration, low specific gravity conductive adhesive that has good conductivity even with half the silver content of conventional adhesives, using a specially shaped TK silver powder, and succeeded in mass production for the first time in the world. |

| How does a low-silver, low-specific gravity conductive adhesive affect the cost? It seems to me that if the amount of silver in the adhesive is reduced, the cost will be reduced... The details are explained in the next point. |

| Conductive adhesives with a low silver concentration are already used in many electronic devices, not only because of the lower cost, but also because the cost is stable since the price is not affected by the market price of silver. |

|

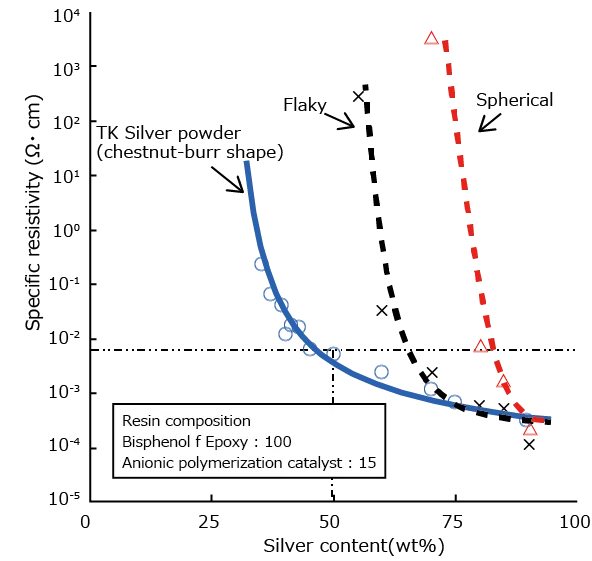

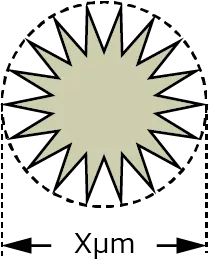

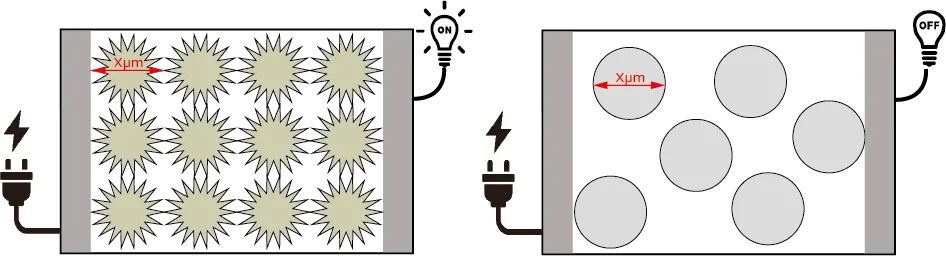

| Chestnut-burr like shaped TK silver powder is used in conductive adhesives with low silver concentration. The graph below shows that compared to common spherical or flake conductive particles, the chestnut-burr like shaped TK silver powder shows conductivity at low concentrations. |

|

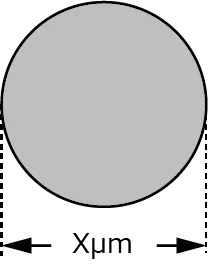

| The conductive adhesive with 50wt% (weight perctage) of chestnut-burr like TK silver powder and the conductive adhesive with 80wt% of spherical silver powder have almost the same conductivity, but the specific gravity of the conductive adhesive is 2.1 for the conductive adhesive with 50wt% chestnut-burr like TK silver powder and 4.0 for the conductive adhesive with 80wt% spherical silver powder. *1 |

| Comparing this in terms of volume per kg, the conductive adhesive using spherical silver powder is about 250 ml, and the conductive adhesive using TK silver powder is about 480 ml. |

| The low silver and low specific gravity type conductive adhesive using TK silver powder is a very low-cost conductive adhesive because it has good conductivity even with a low silver content and can be applied in about twice the amount of conventional products with equivalent conductivity. |

*1 Calculate based on the assumption of specific gravity of the epoxy binder is 1.2, and the specific gravity of silver is 10.5.

| Shape of silver powder | Chestnut-burr like shape |

Spherical |

|---|---|---|

| Silver content | 50wt% | 80wt% |

| Specific gravity | 2.1 | 4.0 |

| Image of adhesive capacity at the same weight |

|

|

| Specific resistivity (ref.) | 10-3Ω・cm level | 10-3Ω・cm level |

Why can electricity be conducted at a low concentration if it is in chestnut-burr like shape?

As explained in "What is a conductive adhesive", conductive particles in a conductive adhesive conduct electricity when they come into contact with each other. The chestnut-burr like shape has more voids than the spherical shape, and even though they are the same size (diameter), the density of the silver is lower and the particles are lighter.

Even if the amount of conductive particles in spherical silver powder is not enough to make contact with each other, the small density and light weight of chestnut-burr like shaped TK silver powder allows the particles to make contact with each other, forming a low-density network that conducts electricity efficiently. It can be said that the chestnut-burr like shaped TK silver powder is a convenient shape to conduct electricity with low silver concentration.

| Chestnut-burr silver powder | Spherical silver powder | |

|---|---|---|

|  | |

| True density | 10.5 | 10.5 |

| Porosity | 40~70vol.% | 0vol.% |

| Bulk density | 1~2 | 3~5 |

|

|

Trouble solution

|

|---|---|

|

Trouble solution

|

|

Products information

|

KAKEN TECH, MICROCLEANER, MICROCLEAN&MARKLESS and MARKLESS are trademarks of KAKEN TECH CO., LTD. in PRC.

KAKEN TECH is a trademark of KAKEN TECH CO., LTD. in the U.S..

| Inquiry |