- Company

- Products

- Technical report

- Indusrial cleaning

- Micro Joining and Assembly Technology

- Ultrasonic technology

- Trouble solution

- Cleaning

- Removing

- Attaching

- PCB Columns

Flux cleaning is essential to ensure the reliability of high-density mounting boards.

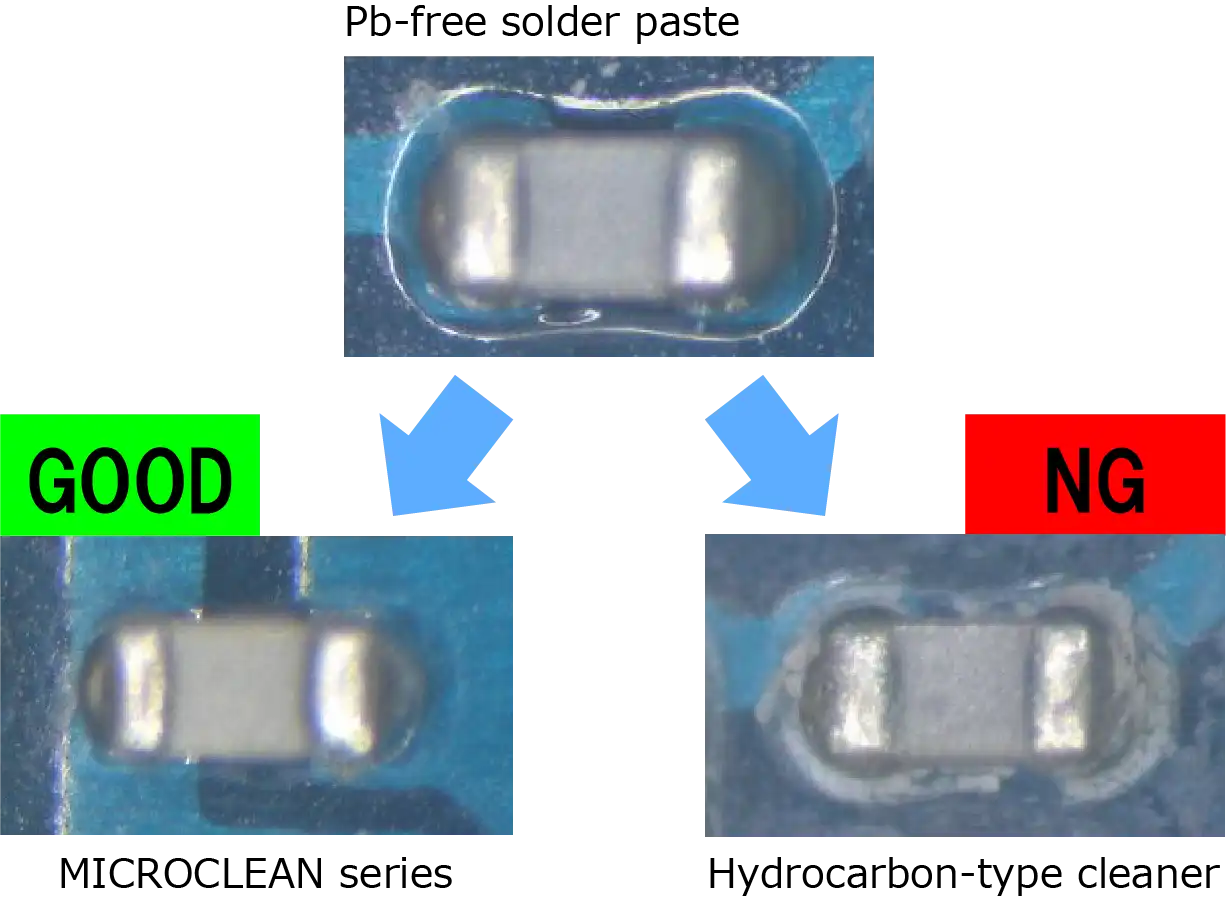

In recent years, as electronic devices have become denser and faster, the importance of flux cleaning has been reevaluated from the standpoint of ensuring reliability. On the other hand, lead-free and halogen-free solder fluxes are increasingly difficult to clean with conventional cleaning agents. KAKEN TECH®'s MICROCLEAN&MARKLESS® series of flux cleaners demonstrate outstanding cleaning performance for lead-free and halogen-free solder fluxes that are difficult to clean with conventional glycol- and hydrocarbon-based cleaning agents! The series is used in many SMT lines both in Japan and overseas.

KAKEN TECH® has developed and proposed a unique cleaning process using a glycol-based cleaning agent MICROCLEAN + a water-containing alcohol rinse agent MARKLESS ®. KAKEN TECH®'s original cleaning agents and rinsing agents cover the disadvantages of hydrocarbon-based cleaning agents and semi-aqueous cleaning systems.

|

|

High-frequency design is essential for electronic substrates and components used in recent communication devices and modules, and low transmission loss is required for substrate materials. While substrate manufacturers are demanding low dielectric constant material characteristics, KAKEN TECH® designs cleaning agents that place the highest priority on not changing the characteristics of circuit surfaces during the cleaning process.

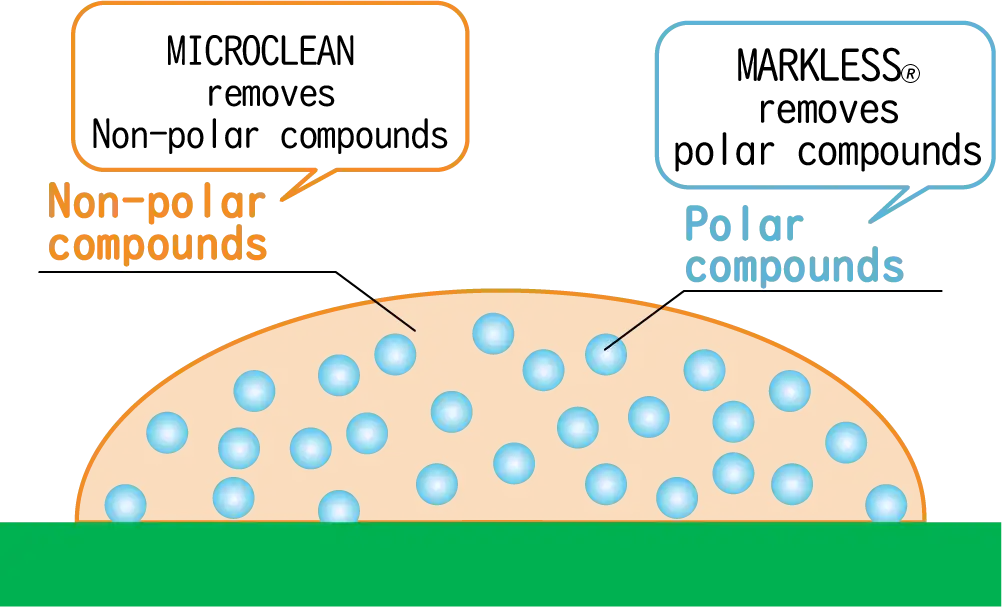

As explained on『What is flux residue?』 page, flux residue is composed of components such as rosin, unreacted activators, thixotropes, and metal salts (such as Sn salts), which can be largely classified into non-polar (lipophilic) and polar (hydrophilic) components.

<Flux Residue Model>

KAKEN TECH®'s flux cleaning system efficiently and completely removes flux residue because the MICROCLEAN series of cleaning agents removes non-polar components and the MARKLESS® rinsing agents remove polar components.

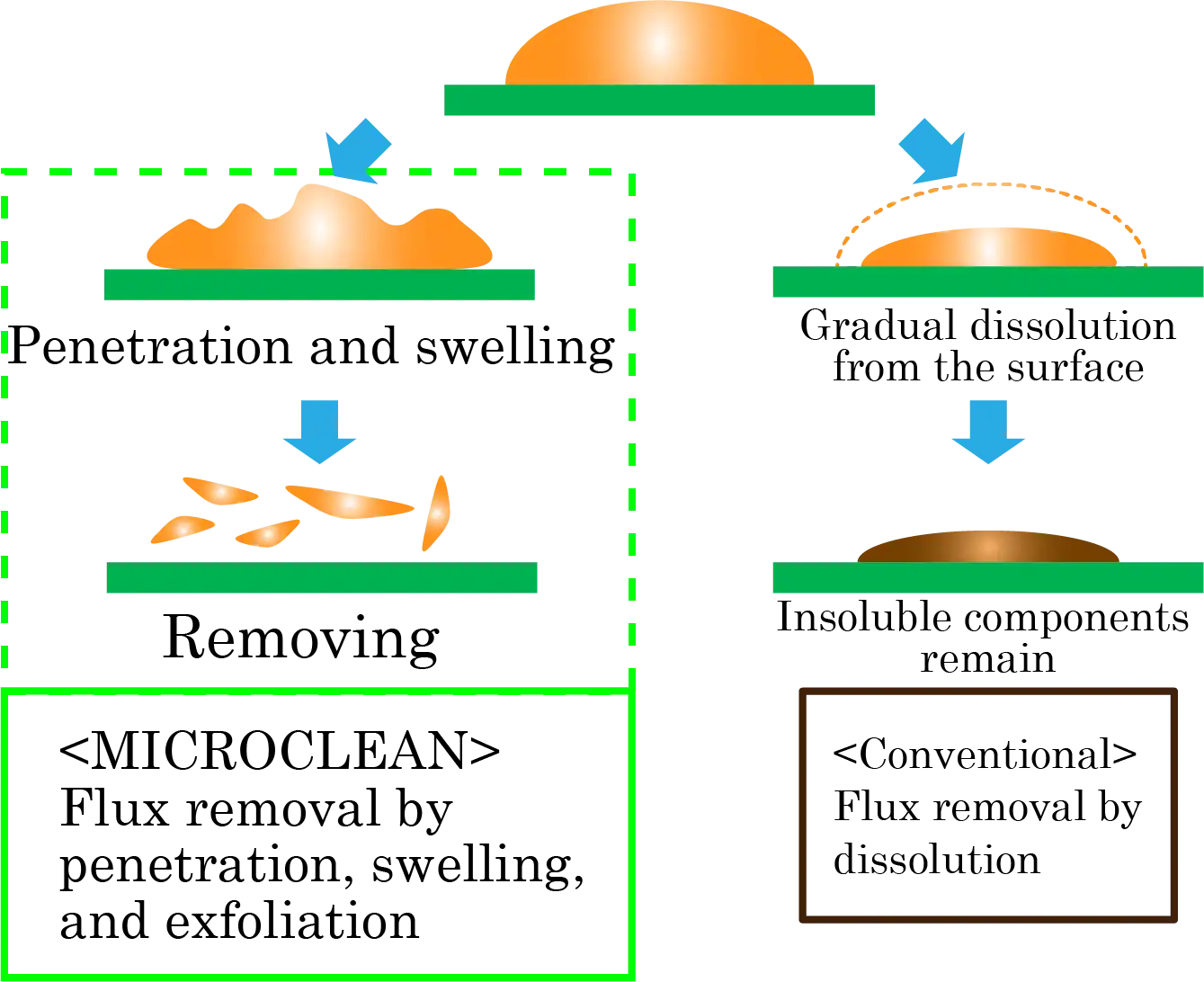

Lead-free solder flux residue contains metal salts and other hard-to-dissolve components, making it difficult to completely remove flux residue with conventional cleaning agents that focus only on dissolving power. KAKEN TECH®'s MICROCLEAN series of flux cleaning agents not only has the ability to dissolve flux, but also has a mechanism to penetrate the flux residue film that is difficult to dissolve, causing it to swell and peel off, thereby achieving high flux cleaning power.

|

|

KAKEN TECH® has developed MARKLESS ®ST-05, a hydrous alcohol-based rinsing agent for flux cleaning, instead of a water rinse.

The following is a comparison with the water rinse process of semi-aqueous cleaning systems, which are often considered together.

| MARKLESS® has low surface tension and is highly effective in rinsing even the smallest gaps such as under chips. In addition, the cleaning agent can be substituted without the need for a surfactant in the cleaning agent, so circuit characteristics are not altered. | |

Water rinse would be... |

The high surface tension of water makes it difficult for the cleaning agent to penetrate into the gaps, resulting in insufficient displacement of the cleaning agent, which leaves behind residual liquid. Therefore, a surfactant is added to the cleaning agent to make the PCB surface hydrophilic, and the surfactant lowers the surface tension of the water to improve water penetration into the gaps. However, if this surfactant remains on the surface of the printed circuit board, it causes a degradation of circuit characteristics such as dielectric properties. |

|---|---|

| MARKLESS® dries almost as fast as alcohol (IPA). The drying property of gaps can also dry at about 1/4 the speed compared to water. It is also characterized by the fact that it is less likely to produce watermarks than water when dried. | |

Water rinse would be... |

Water is not easy to dry, which leads to issues such as longer drying times and higher drying temperatures, which increase energy consumption. In addition, because of its high surface tension, microscopic foreign matter contained in water tends to concentrate as the water dries, resulting in water marks (water spots or drying marks). |

|---|---|

| MARKLESS® is a mixture of water and alcohol. Although it contains water, the properties of alcohol inhibit metal corrosion, lead decay, and rot. | |

Water rinse would be... |

Frequent water changes and wastewater are required because the water may corrode metals, which is labor intensive and costly. In addition, it is difficult to prevent water corrosion, and algae and fungi generated by decay often cause foreign matter problems in the cleaning process. |

|---|---|

| The Distiller(Distillation and recycling device), which is a standard feature of the MICROCLEANER® cleaning system, enables recycling of rinsing agent in the equipment, thus enabling operation at low cost. In addition, only the concentrated residue cut by distillation recycling is used as waste liquid, thus significantly reducing the amount of waste liquid. | |

Water rinse would be... |

Water used in the water rinse process can also be recycled, but purifying the water requires large amounts of energy and equipment such as high-performance membranes (water treatment membranes), which are costly. In addition, if the plant does not have wastewater treatment facilities, wastewater treatment is also costly. |

|---|---|

| Products | Claning agent | Rinse agent | ||

|---|---|---|---|---|

| MICROCLEAN WS-3220U |

MICROCLEAN WS-2107U |

MICROCLEAN RW-4180U |

MARKLESS® ST-05U |

|

| Merit | Pb-free compatible (utility type) |

Pb-free compatible (For difficult to clean) |

Non DG type | - |

| Main ingredient | Alcoholic | Alcoholic | Glycol-based | Alcoholic |

| Specific gravity (20℃) |

1.00 | 1.05 | 0.98 | 0.89 |

| Viscosity mPa.s(20℃) |

9.3 | 9.7 | 11.0 | 2.3 |

| Surface tension mN/m(20℃) |

35 | 44 | 36 | 26 |

| Boiling point (℃) |

200以上 | 200以上 | 100以上 | 81 |

| Flash point (℃) |

105 | 100 | - | 24 |

| Ozone destruction coefficient |

0 | 0 | 0 | 0 |

We also have many other part numbers in our lineup. If you would like to receive more information, please contact us using the inquiry form at the bottom of this page.

We also accept requests for selection of cleaning agents and cleaning tests! If you have any questions about flux cleaning, please contact us using the inquiry form at the bottom of this page.

|

Products information

|

|---|

|

Technial report

|

|---|---|

|

Technial report

|

|

Trouble solution

|

|

Trouble solution

|

| Inquiry and question |

| Please be as specific as possible in your inquiry. Depending on the contents of your inquiry, it may take some time for us to reply to you. For SDS, please contact us from [Requests for SDS] in the upper right corner. ※Sales through the inquiry form are strictly prohibited. |

KAKEN TECH, MICROCLEANER, MICROCLEAN&MARKLESS and MARKLESS are trademarks of KAKEN TECH CO., LTD. in PRC.

KAKEN TECH is a trademark of KAKEN TECH CO., LTD. in the U.S..