- Company

- Products

- Technical report

- Indusrial cleaning

- Micro Joining and Assembly Technology

- Ultrasonic technology

- Trouble solution

- Cleaning

- Removing

- Attaching

- PCB Columns

|

| PALLETCLEANER®series is cleaning equipment for flux that has adhered to pallets (also called carrier pallets, carriers, or dip pallets) used in the wave soldering process. Instead of ultrasonic or brush cleaning, which could deform the palette opening, we use a shower-type system. |

| Live demonstrations are being accepted! We can take your work and carry out a cleaning demonstration using actual equipment. Please contact us using the inquiry form at the bottom of the page! |

The “PALLETCLEANER®” shower-type cleaning machine and the dedicated cleaning agent “PALLECLEAN” achieve powerful cleaning in a short time!

| ✓Reduced work time | ||

| Up to 15 carrier pallets can be loaded at once for cleaning. Cleaning is completed faster than scrubbing by hand! | |

| Even the time-consuming and labor-intensive draining process can be completed without getting your hands dirty simply by setting the oil can and opening the tap. *Only for the PCLT series. | ||

| ✓High cleaning power | ||

| The “PALLETCLEAN” series of dedicated cleaning agents powerfully removes flux stains from carrier pallets. | |

| A wide range of products, including low-odor and low-VOC types, are available to improve the work environment. | ||

| Free of non-volatile ingredients, so no need for a rinse after cleaning! | ||

| ✓Cost reduction | ||

| The shower cleaning does not damage the pallet like brushing or ultrasonic cleaning, so the pallet lasts longer. | |

| Simple structure, no complicated maintenance, and low running costs. | ||

| Along with reducing the amount of work time, it is also possible to reduce labor costs. | ||

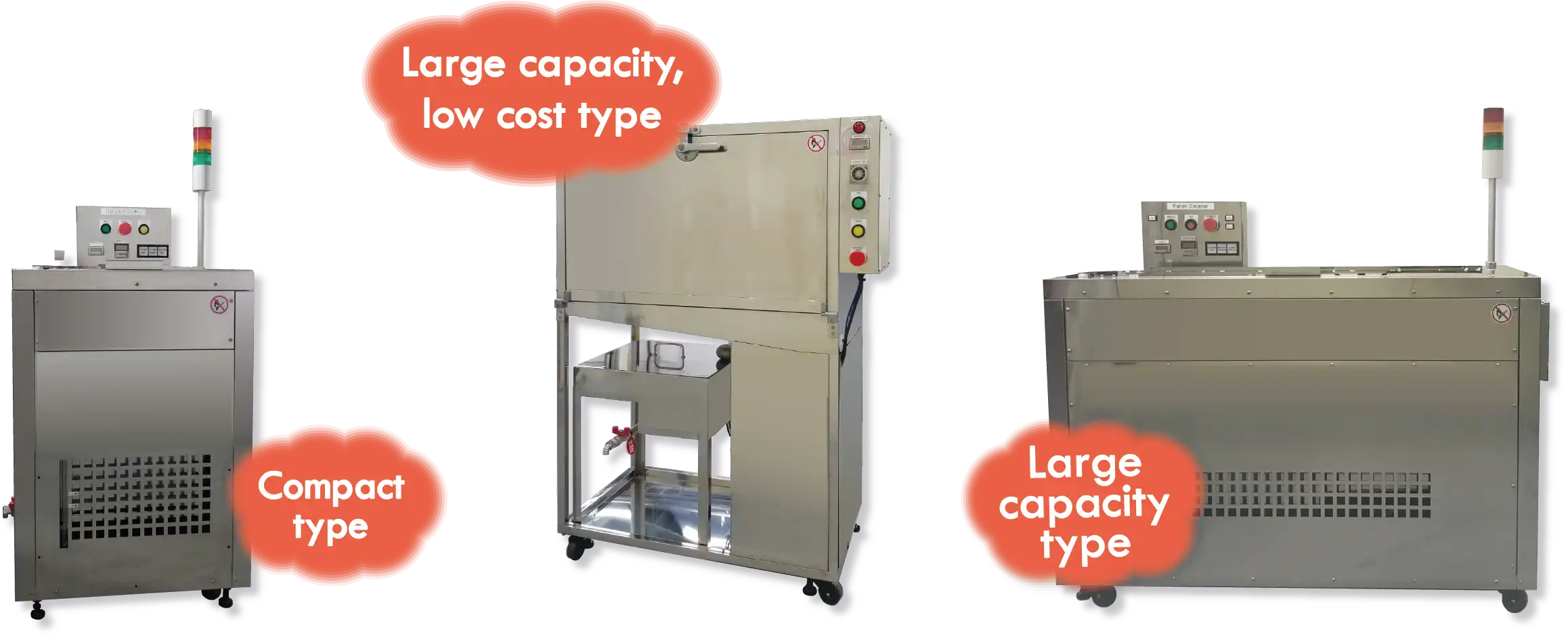

We have a lineup of three models to suit your pallets size and processing volume!

|

Low-cost, large-capacity model PCLT | |||||||

|---|---|---|---|---|---|---|---|---|

| ||||||||

|

Compact model PCM | |||||||

| ||||||||

|

High-capacity model PCL-001 | |||||||

| ||||||||

Let's take a look at the flux removal performance of PALLETCLEAN at the carrier pallet opening.

|  |

| Model:PALLETCLEANER®PCM Chemical:PALLETCLEAN PA-series Cleaning time:1min | |

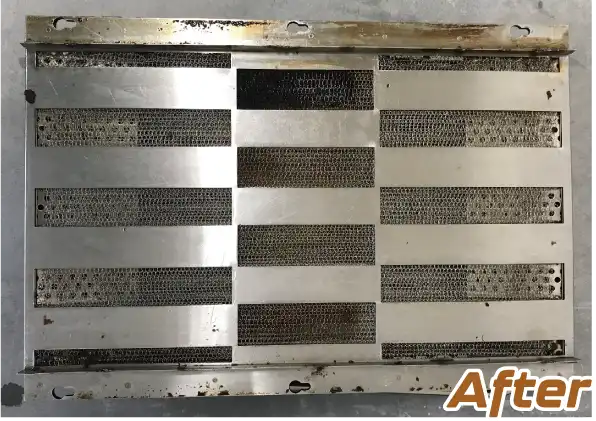

The PALLETCLEANER® can also be used to clean large carrier pallets and reflow oven parts.

|  |

| Model:PALLETCLEANER®PCLT Chemical:PALLETCLEAN PA-series Cleaning time:15min | |

The newly developed PALLETCLEANER® PCLT can clean not only carrier pallets, but also parts inside reflow ovens. See for yourself how much flux (resin dirt) that has built up thickly on large parts (approx. 30cm x 50cm) can be cleaned in just 30 minutes.

In addition to the series of steps involved in supplying the PALLETCLEANER® with fluid, setting the palette, starting the cleaning (just press the button!), drying, and draining the fluid, we have also included information on the safety specifications in this video, which is packed with all the information you need when looking into purchasing a PALLETCLEANER®!

|

Products information

|

|---|

|

Trouble solution

|

|---|

| Inquiry and question |

| Please be as specific as possible in your inquiry. Depending on the contents of your inquiry, it may take some time for us to reply to you. For SDS, please contact us from [Requests for SDS] in the upper right corner. ※Sales through the inquiry form are strictly prohibited. |

KAKEN TECH, MICROCLEANER, MICROCLEAN&MARKLESS and MARKLESS are trademarks of KAKEN TECH CO., LTD. in PRC.

KAKEN TECH is a trademark of KAKEN TECH CO., LTD. in the U.S..