- Company

- Products

- Technical report

- Indusrial cleaning

- Micro Joining and Assembly Technology

- Ultrasonic technology

- Trouble solution

- Cleaning

- Removing

- Attaching

- PCB Columns

In recent years, as electronic devices have become smaller and mounted more densely, electronic circuits and components have required increasingly higher quality and reliability, and the need for flux cleaning has increased.

MICROCLEANER® is the definitive flux cleaner! It contributes to the quality improvement of printed circuit boards and electronic components.

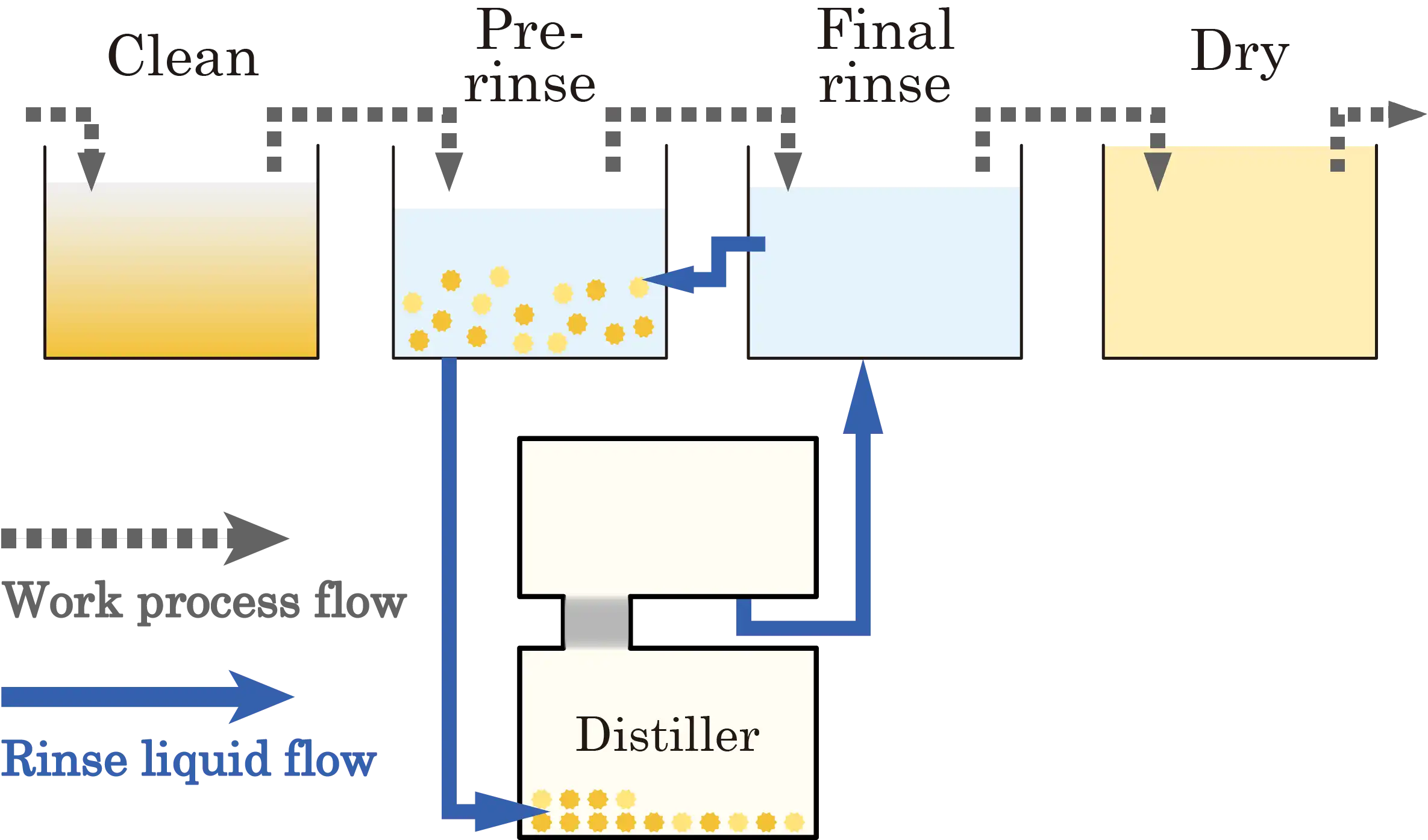

The flux cleaner MICROCLEANER® consists of four tanks: cleaning tank, rinsing tank, final rinsing tank, and drying tank.

The equipment is equipped with a compact Distillation and recycling device as standard equipment, and the rinse solution is continuously purified and recycled, resulting in a system that combines high cleaning quality with no waste liquid and low running costs.

We can also design and manufacture cleaning equipment with automatic transporters according to workpiece size, throughput, and customer requirements.

A video of the actual MICROCLEANER® is also available for your viewing.

The equipment specifications below are examples. We can design and manufacture cleaning machines according to the size of workpieces to be cleaned, the amount of cleaning, and other customer requirements.

This is a compact, manual transfer type flux cleaner. Many prototype and R&D departments use this machine.

| Model | MC3HD-1.5E |  |

|---|---|---|

| Dimension | W.1,230 x D.850 x H.1,200mm | |

| Power supply | 3-phase 200V | |

| Tank configuration | Cleaning tank, pre-rise tank, Final rinse tank, dry tank | |

| Cleaning Capacity | A5 size 80sheets/8h | |

| Tank size (Opening) | W.100 x D.300mm | |

| Tank capacity | Approx9L | |

| Applicable substrate size | max.200 x 165mm | |

| Distiller | In-unit distillation and regeneration | |

| Required accessory | Exhaust system and cooling water supply system |

This is a large, manual transfer type flux cleaner. It is used in many mounting processes, including mass production and EMS companies.

| Model | MC3HD-6E |  |

|---|---|---|

| Dimension | W.2,000 x D.1200 x H.1,810mm | |

| Power supply | 3-phase 200V | |

| Tank configuration | Cleaning tank, pre-rinse tank, final rinse tank, Dry tank | |

| Cleaning capasity | A4 size 160sheet/8h | |

| Tank size(opening) | W.200 x D.500mm | |

| Tank capacity | Approx. 50L | |

| Applicable substrate size | max.370 x 345mm | |

| Distiller | In-unit distillation and regeneration | |

| Required accessory | Exhaust system and cooling water supply system |

This is a large flux cleaner with an automatic transfer mechanism. It is used in many mounting processes, including mass production and EMS companies.

| Model | MC4HD-6E-AS |  |

|---|---|---|

| Dimension | W.4,000 x D.1200 x H.1,900mm | |

| Power supply | 3-phase 200V | |

| Tank configuration | Cleaning tank, pre-rinse tank, final rinse tank, Dry tank | |

| Cleaning capacity | A4 size 500sheet/8h | |

| Tank size(opening) | W.200 x D.500mm | |

| Tank capacity | Approx. 50L | |

| Applicable substrate size | max.370 x 345mm | |

| Distiller | In-unit distillation and regeneration | |

| Required accessory | Exhaust system and cooling water supply system |

|

Products information

|

|---|---|

|

Products information

|

|

Technial report

|

|---|---|

|

Technial report

|

|

Trouble solution

|

|

Trouble solution

|

| Inquiry and question |

| Please be as specific as possible in your inquiry. Depending on the contents of your inquiry, it may take some time for us to reply to you. For SDS, please contact us from [Requests for SDS] in the upper right corner. ※Sales through the inquiry form are strictly prohibited. |

KAKEN TECH, MICROCLEANER, MICROCLEAN&MARKLESS and MARKLESS are trademarks of KAKEN TECH CO., LTD. in PRC.

KAKEN TECH is a trademark of KAKEN TECH CO., LTD. in the U.S..