- Company

- Products

- Technical report

- Indusrial cleaning

- Micro Joining and Assembly Technology

- Ultrasonic technology

- Trouble solution

- Cleaning

- Removing

- Attaching

- PCB Columns

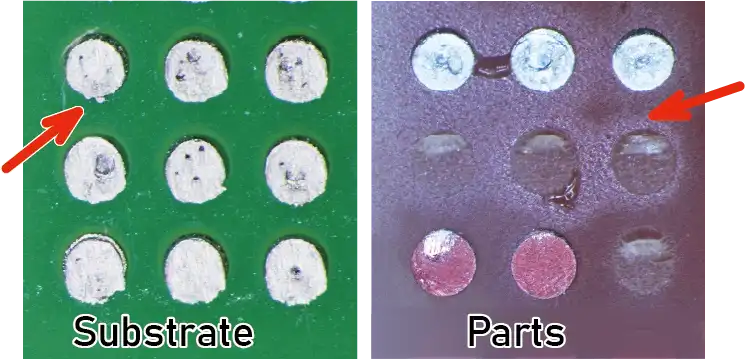

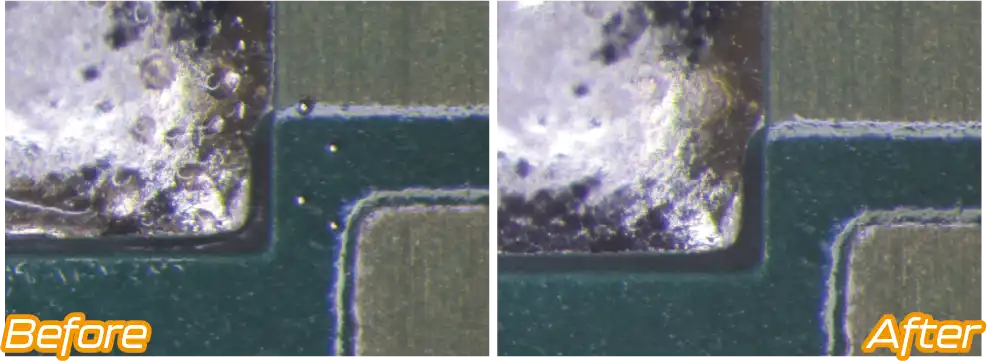

Flux cleaning, that is essential for high-density packaging.In the midst of tightening regulations on chemical substances, such as the discontinuation of production of HCFCs and the addition of GB standards for cleaning agents to China's VOC regulations, KAKEN TECH has developed the MICROCLEAN ECO & MARKLESS ECO Series, high-performance, low-VOC cleaning liquid that combine even higher precision cleaning with environmental friendliness.

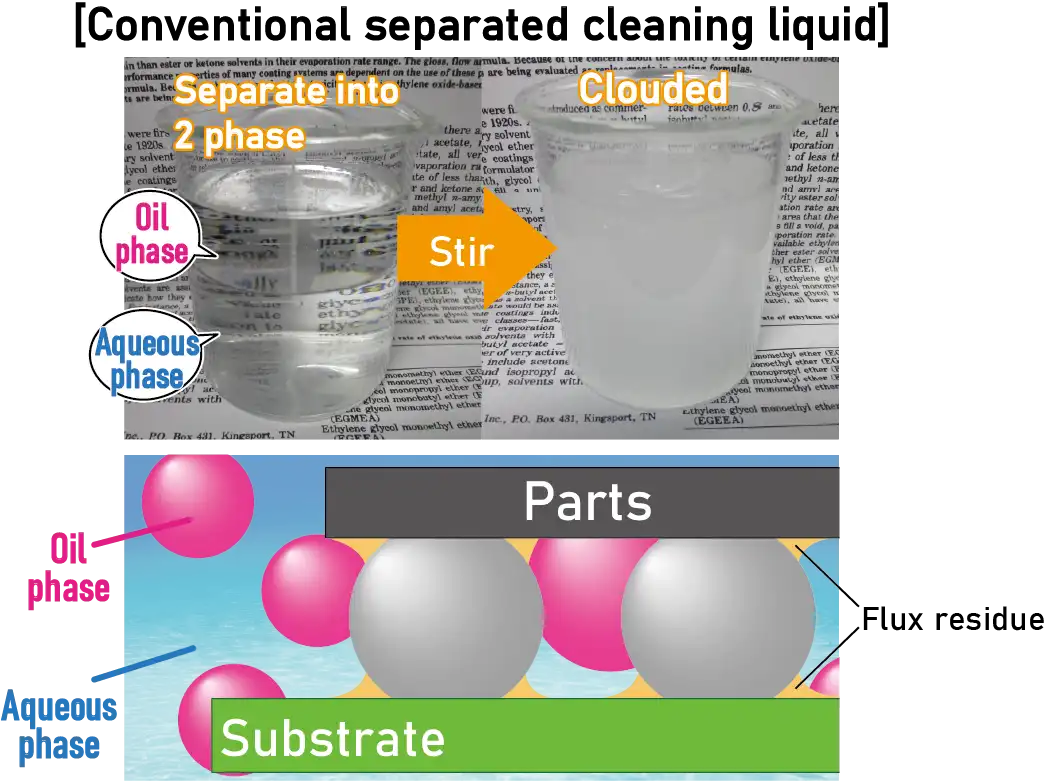

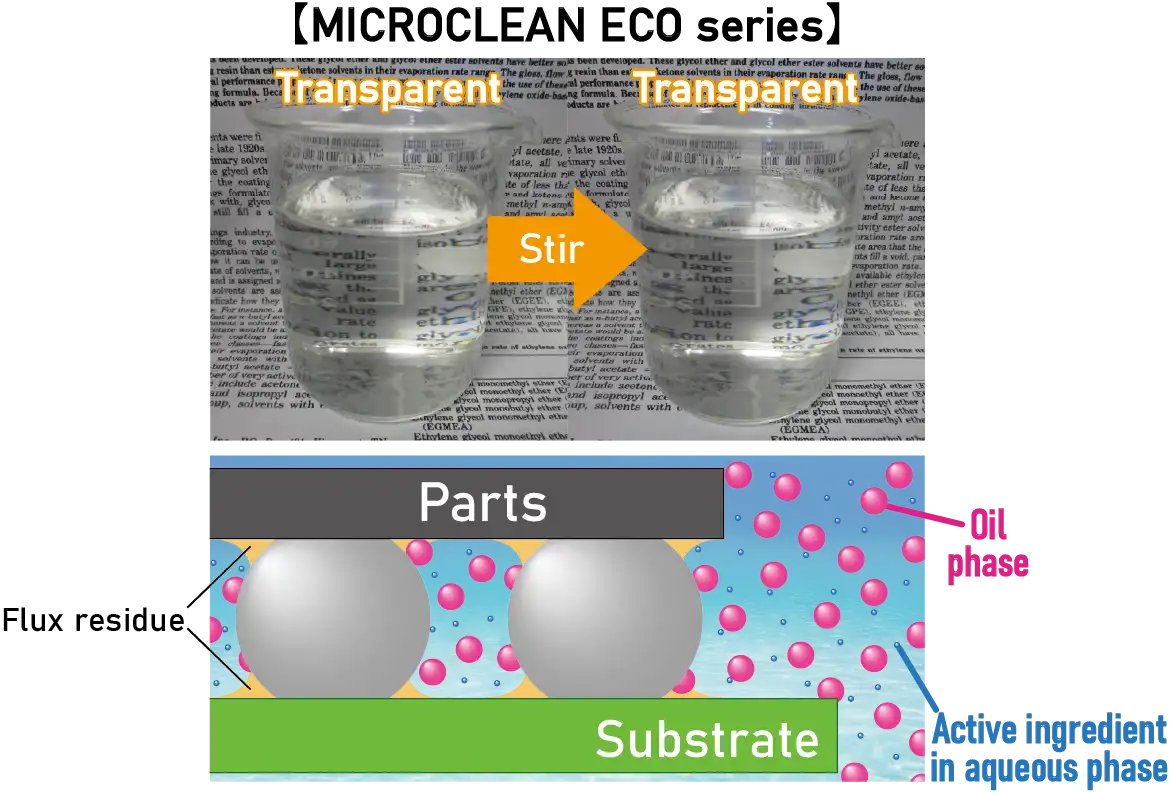

KAKEN TECH's conventional low-VOC cleaning liquids effectively clean flux residues with components that are phase-separated into an oil phase and an aqueous phase. The newly developed MICROCLEAN ECO series miniaturizes the oil phase to nano size, and powerfully removes flux residue in narrow gaps that cannot be removed by conventional cleaning liquid.

|

|

|

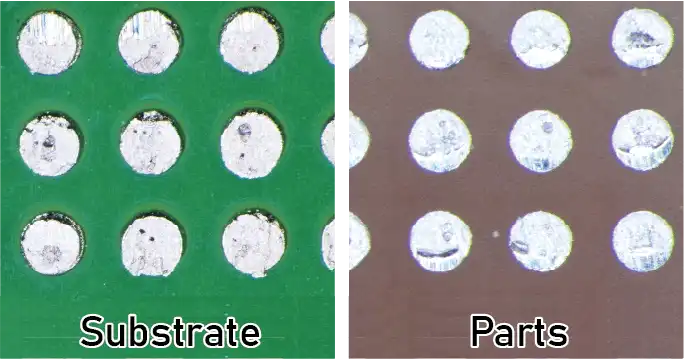

☝Excellent narrow gap cleaning and particle removal |

☝Eco-friendly low VOC, and non Dangerous goods |

| Test piece:PKGparts / gap 30um | |

|---|---|

|

|

| Cleaning condition: MICROCLEAN ECO series 50℃ x 10min High-speed liquid flow |

Cleaning condition: Semi-aqueous cleaning agent 60℃ x 10min High-speed liquid flow |

| 【Minute solder ball】 | |

|---|---|

| |

| Target particle size: 30~50um Cleaning condition: MICROCLEAN ECO series(50℃ x 1min with Ultrasonic) | |

| 【Foreign particleas adhering in the process】 | |

|---|---|

Sebum and fragments |

Aluminum particles |

| Target particle size: Sebum and fragments / Ave.30um, Aluminum particles / approx.2um Cleaing condition: MICROCLEAN ECO series(50℃ x 1min with ultrasonic) | |

| Product# | Cleaning liquid MICROCLEAN ECO-8100U |

Rinse liquid MARKLESS ECO-R81U |

|---|---|---|

| Specific gravity |

0.98 | 0.98 |

| Viscosity (mPa・s) |

4 | 3 |

| Surface tention (mN/m) |

32 | 31 |

| Boiling point | 100℃ or higher | |

| Flash point | None | |

| ODP | 0 | |

| UNRTDG | UN Class : N/A UN No. : N/A |

|

| VOC regulation in China (GB38508-2020) |

Semi-aqueous cleaning agent | |

Flux cleaning (PCB cleaning) is indispensable for ensuring the reliability of high-density mounting boards.

KAKEN TECH offers one-stop cleaning solutions by taking advantage of its strength in developing, designing, manufacturing, and selling both flux cleaning equipment and cleaning agents in-house.

In response to the requests from customers who are considering flux cleaning but cannot imagine how the equipment works, KAKEN TECH will introduce the mechanism and movement of the MICROCLEANER, flux cleaning system, using full computer graphics animation.

We have also prepared a video showing the actual MICROCLEANER.

|

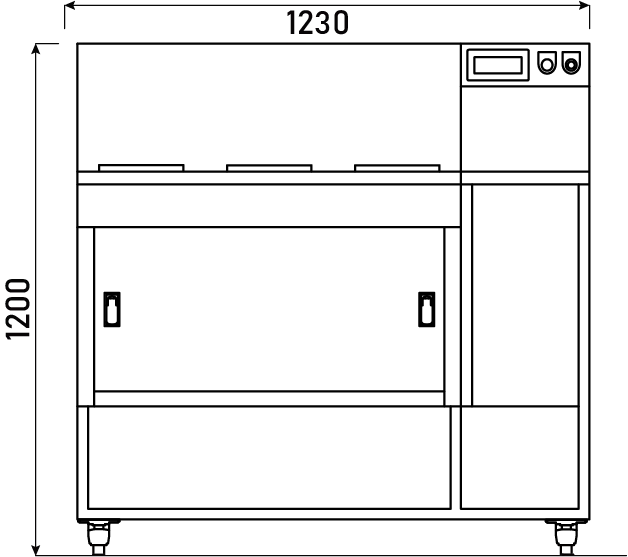

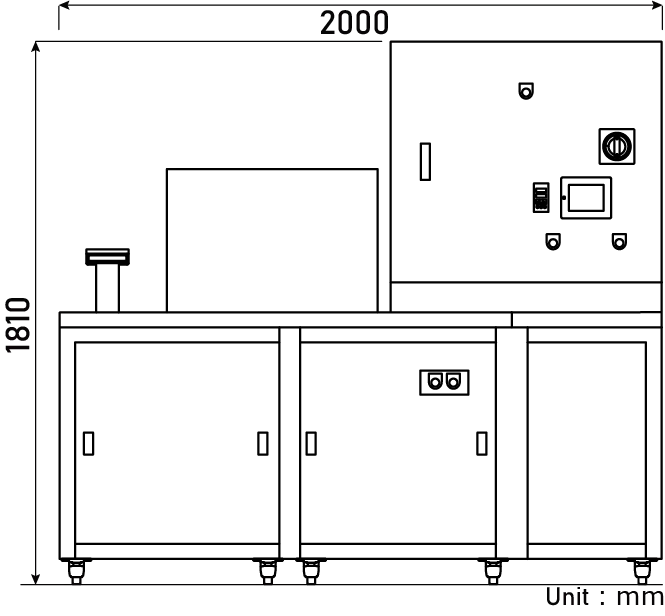

☆The rinse liquid is continuously recycled by the compact Distiller that comes as standard equipment, and the system achieves both high cleaning quality and low running cost with no waste fluid. |

| Model | MC3HD-1.5E |

Machine appearance |

|---|---|---|

| External dimension | W.1,230 x D.850 x H.1,200mm |  |

| Power input | 3-phase 200V | |

| Tank configuration | Cleaning, Rinse1, Rinse2, Dry | |

| Processing capacity | A5size 280 sheet/8h | |

| Tank size(opening) | W.100 x D.300mm | |

| Tank capacity | Approx. 9L | |

| Applicable substrate size | max.200 x 165mm | |

| Distiller | Built-in Distiller | |

| Additional equipment required | Ventilation, coolant supplier |

| Model | MC3HD-6E |

Machine appearance |

|---|---|---|

| External dimension | W.2,000 x D.1200 x H.1,810mm |  |

| Power input | 3-phase 200V | |

| Tank configuration | Cleaning, Rinse1, Rinse2, Dry | |

| Processing capacity | A4 size 600sheet/8h | |

| Tank size(opening) | W.200 x D.500mm | |

| Tank capacity | Approx. 50L | |

| Applicable substrate size | max.370 x 345mm | |

| Distiller | Built-in Distiller | |

| Additional equipment required | Ventilation, coolant supplier |

Automatic machines can also be designed and manufactured according to workpiece size, processing volume, and customer requirements.

|

Technial report

|

|---|---|

|

PCB Mounting Columns

|

|

Trouble solution

|

| Inquiry and question |

| Please be as specific as possible in your inquiry. Depending on the contents of your inquiry, it may take some time for us to reply to you. For SDS, please contact us from [Requests for SDS] in the upper right corner. ※Sales through the inquiry form are strictly prohibited. |