- Company

- Products

- Technical report

- Indusrial cleaning

- Micro Joining and Assembly Technology

- Ultrasonic technology

- Trouble solution

- Cleaning

- Removing

- Attaching

- PCB Columns

Masterpiece of the deflux system to improve the cleaning quality of electronic circuits (PCB) and electronic components that require high quality!

|

High cleaning performance and high reliability |

Cost effective with complete recycling system |

|

Dry fast even under the chips |

|

Compact and user friendly design |

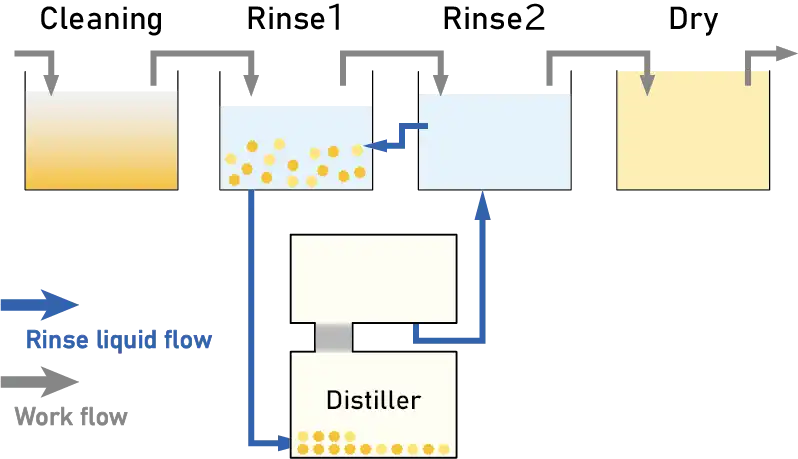

The flux cleaner, MICROCLEANER, consists of four tanks: a cleaning tank, a rinsing tank, a final rinsing tank, and a drying tank.

The machine is equipped with a compact Distiller as standard equipment, and the rinse liquid is continuously purified and recycled, resulting in a system that combines high cleaning quality with no waste liquid and low running costs.

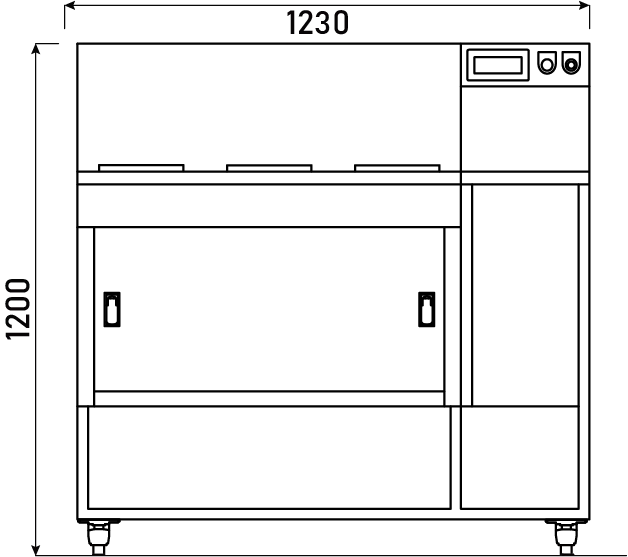

| Model# | MC3HD-1.5E | Machine appearance |

|---|---|---|

| Power input | 3 phase, 200V |  |

| Tank configuration | Cleaning, Rinse1, Rinse2 and Dry | |

| Processing capacity | 280 sheets/8 hours | |

| Applicable work size | Max. 200 x 165 mm | |

| Tank size(opening) | W 100 x D 300 mm | |

| Tank capacity | Approx. 9L | |

| Recycling device | Built-in distiller | |

| Necessary accessories | Ventilation equipment Cooling water supply device |

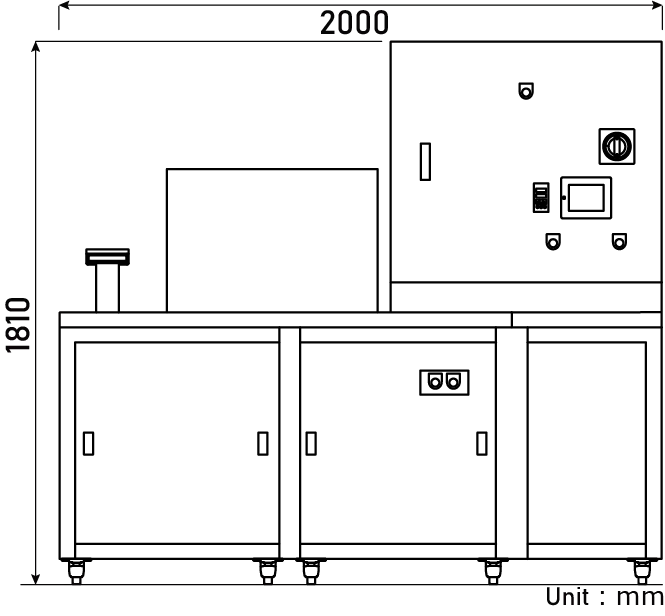

| Model# | MC3HD-6E | Machine appearance |

|---|---|---|

| Power input | 3 phase, 200V |  |

| Tank configuration | Cleaning, Rinse1, Rinse2 and Dry | |

| Processing capacity | 600 sheets/8 hours | |

| Applicable work size | Max. 370 x 345 mm | |

| Tank size(opening) | W 200 x D 500 mm | |

| Tank capacity | Approx. 50L | |

| Recycling device | Built-in distiller | |

| Necessary accessories | Ventilation equipment Cooling water supply device |

|

・Maintain circuit characteristics before and after cleaning. (Focus not only on insulation resistance but also on dielectric properties.) |

| ・High dissolvability and removability of flux residue after soldering, especially ionic compounds, and other process contaminants. | |

| ・No or mere impact on electronic components and other materials Or, the effect is extremely slight. | |

| ・High safety to human body and environment. | |

| ・Stably supplyable and recyclable. |

| Product name | Cleaning chemical | Rinse chemical | |||

|---|---|---|---|---|---|

| MICROCLEAN WS-1014U |

MICROCLEAN WS-3220U |

MICROCLEAN WS-2107U |

MICROCLEAN RW-4180U |

MARKLESS ST-05U |

|

| General purpose |

Lead-free soldering flux (standard) |

Lead-free soldering flux (For difficult cleaning) |

Non-dangerous goods | ||

| Main component | Glycol-based | Alcohol-based | Alcohol-based | Glycol-based | Alcohol-based |

| Specific gravity (20℃) | 0.92 | 1.00 | 1.05 | 0.93 | 0.89 |

| Viscosity mPa.s(20℃) | 7.4 | 9.3 | 7.4 | 11.0 | 2.3 |

| Surface tension mN/m (20℃) | 29 | 35 | 29 | 36 | 26 |

| Boiling point (℃) | 200 or more | 200 or more | 200 or more | 100 or more | 81 |

| Flash point (℃) | 117 | 105 | 117 | - | 24 |

| Ozone deplting potential | 0 | 0 | 0 | 0 | 0 |

| UN Class UN No |

N/A | N/A | N/A | N/A | Class 3 1170 |

|

Products information

|

|---|---|

|

Technial report

|

|

Technial report

|

|

PCB Mounting Columns

|

|

Trouble solution

|

| Inquiry and question |

| Please be as specific as possible in your inquiry. Depending on the contents of your inquiry, it may take some time for us to reply to you. For SDS, please contact us from [Requests for SDS] in the upper right corner. ※Sales through the inquiry form are strictly prohibited. |