- Company

- Products

- Technical report

- Indusrial cleaning

- Micro Joining and Assembly Technology

- Ultrasonic technology

- Trouble solution

- Cleaning

- Removing

- Attaching

- PCB Columns

Flux cleaning is indispensable for ensuring the reliability of high-density mounting substrates. Amidst tightening regulations on chemical substances, such as the discontinuation of CFC substitutes in accordance with environmental regulations and VOC regulations under China's GB standard, KAKEN TECH® has developed the MICROCLEAN ECO & MARKLESS®ECO Series, a high-performance, low-VOC cleaning agent that combines further high-precision cleaning with environmental friendliness.

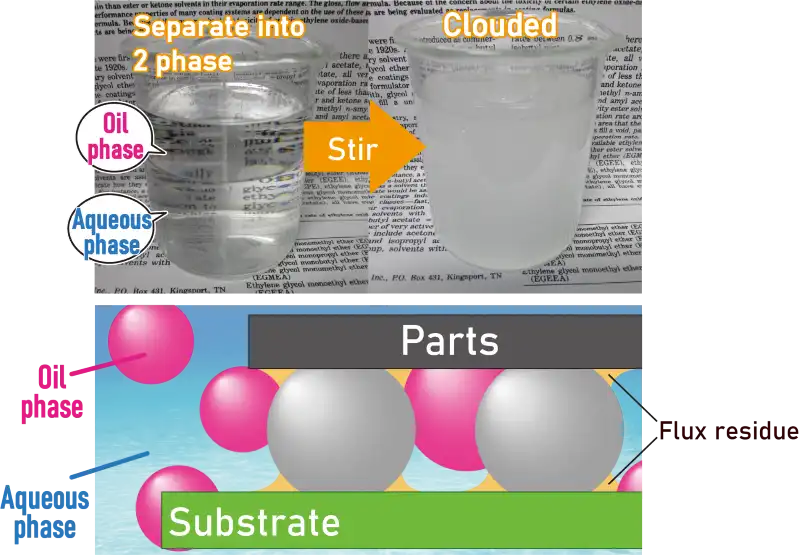

KAKEN TECH had already launched a low-VOC cleaning agent that effectively cleans flux residues using a two-phase separation of the oil and water phases.

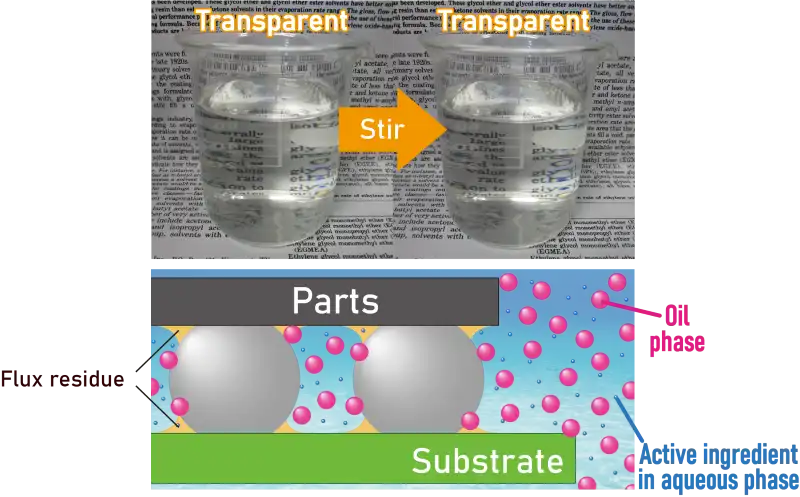

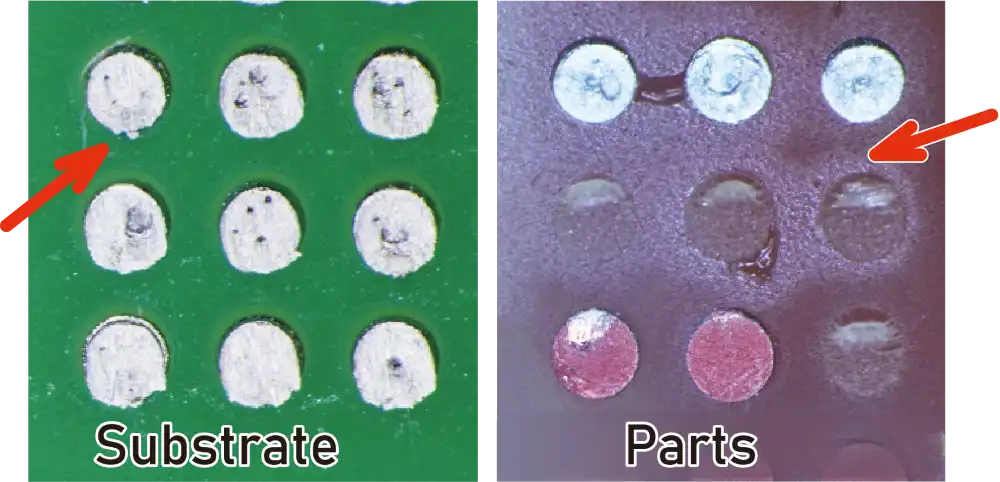

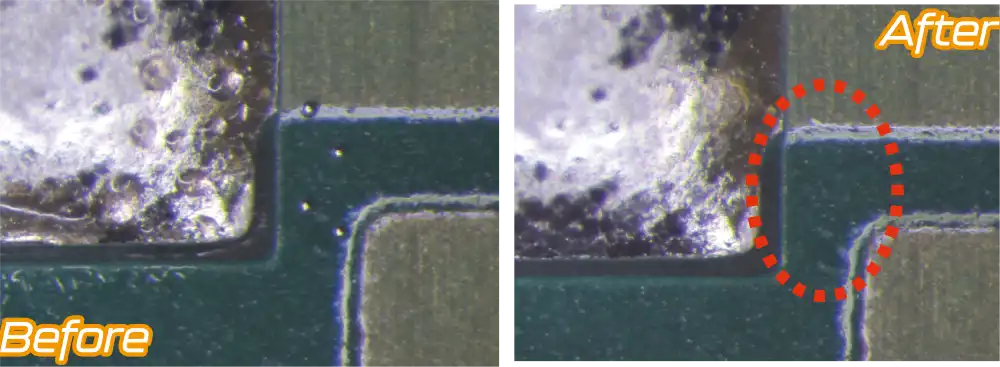

However, with the increase in mounting density, we anticipated an increase in the need for flux cleaning agents for narrower gaps, and began development of a new cleaning agent. By miniaturizing the oil phase of conventional low-VOC cleaning agents down to the nanosize, we have developed a new cleaning agent that is capable of removing flux residue even from narrower gaps, which has been difficult to achieve until now.

| Conventional low-VOC cleaning agent (two-phase separation)  |

MICROCLEAN ECO Series |

|

☝Excellent narrow-gap cleanability and particle removal |

|---|---|

|

☝Environmentally friendly, low VOC, non-hazardous |

MICROCLEAN ECO Series |

Semi-aqueous cleaning agents | |

|---|---|---|

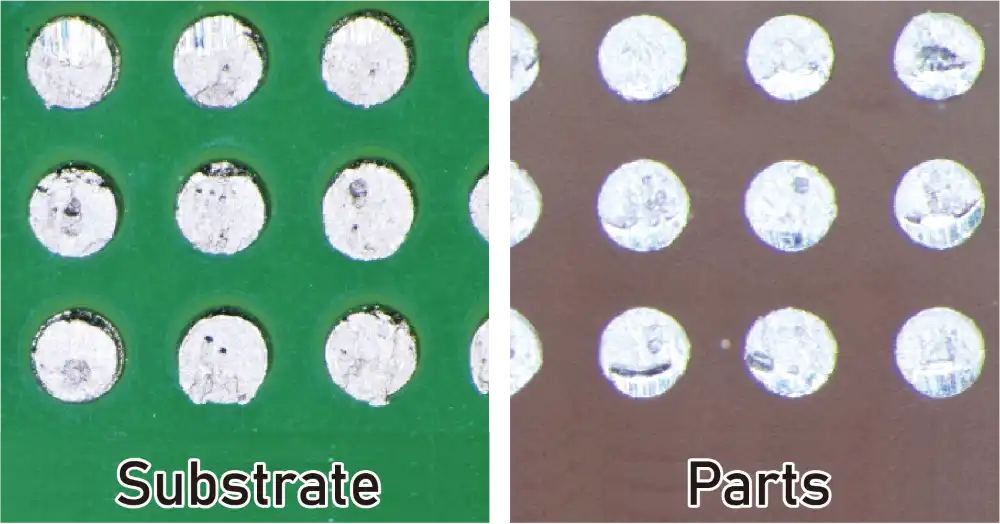

| Cleaning condition: MICROCLEAN ECO Series 50℃/Jet x 10min |

Cleaning condition: Semi-aqueous cleaning agents 60℃/jet x 10min | |

| Work pieces:PKG parts 30um gap | ||

| 【minute solder balls】 | |

| |

| Target particle size:30~50um Cleaning condition:MICROCLEAN ECO series (50℃/jet x 1min) | |

| 【Foreign matter adhered in the process】 | |

Sebum, Sebum fragments |

Alumina Particles |

| Target particle size: sebum・sebum fragments/average 30um, Alumina particles / approx. 2um Cleaning conditions: MICROCLEAN ECO series (50°C / ultrasonic x 1 min) | |

|

Products information

|

|---|

|

Technial report

|

|---|---|

|

Trouble solution

|

|

Trouble solution

|

| Inquiry and question |

| Please be as specific as possible in your inquiry. Depending on the contents of your inquiry, it may take some time for us to reply to you. For SDS, please contact us from [Requests for SDS] in the upper right corner. ※Sales through the inquiry form are strictly prohibited. |

KAKEN TECH, MICROCLEANER, MICROCLEAN&MARKLESS and MARKLESS are trademarks of KAKEN TECH CO., LTD. in PRC.

KAKEN TECH is a trademark of KAKEN TECH CO., LTD. in the U.S..