- Company

- Products

- Technical report

- Indusrial cleaning

- Micro Joining and Assembly Technology

- Ultrasonic technology

- Trouble solution

- Cleaning

- Removing

- Attaching

- PCB Columns

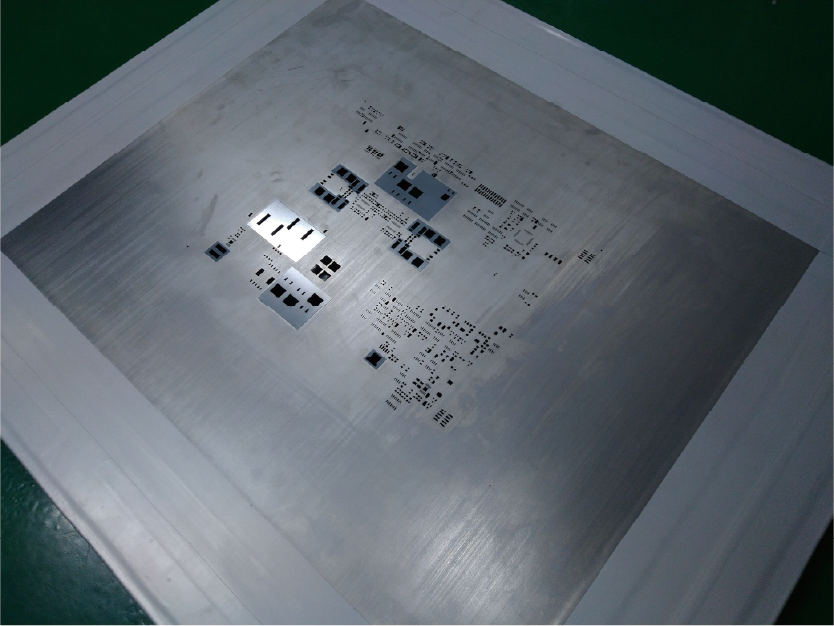

The process of printing solder paste using an SMT stencil is one of the most important processes in the circuit board (PCB) mounting process.

In fact, it is said that 70% of product defects in the mounting process are caused by the solder paste printing process, and cleaning the SMT stencil is the key to improving the quality of the printing process.

If the openings in the SMT stencil are blocked by dirt or other matter, there is a risk of defects such as insufficient solder being printed or excess solder paste being printed.

Furthermore, if the pitch becomes narrower due to the increased density of mounting, there is a risk that manual cleaning using a wiping cloth soaked in IPA will not be able to completely clean and remove the solder paste or solder particles.

|

On this page, we have verified the cleaning performance of a dirty SMT stencil when cleaned using |

|

We hope that you will re-check the cleaning agents and methods used in your company, and use the content of this page to update your cleaning processes.

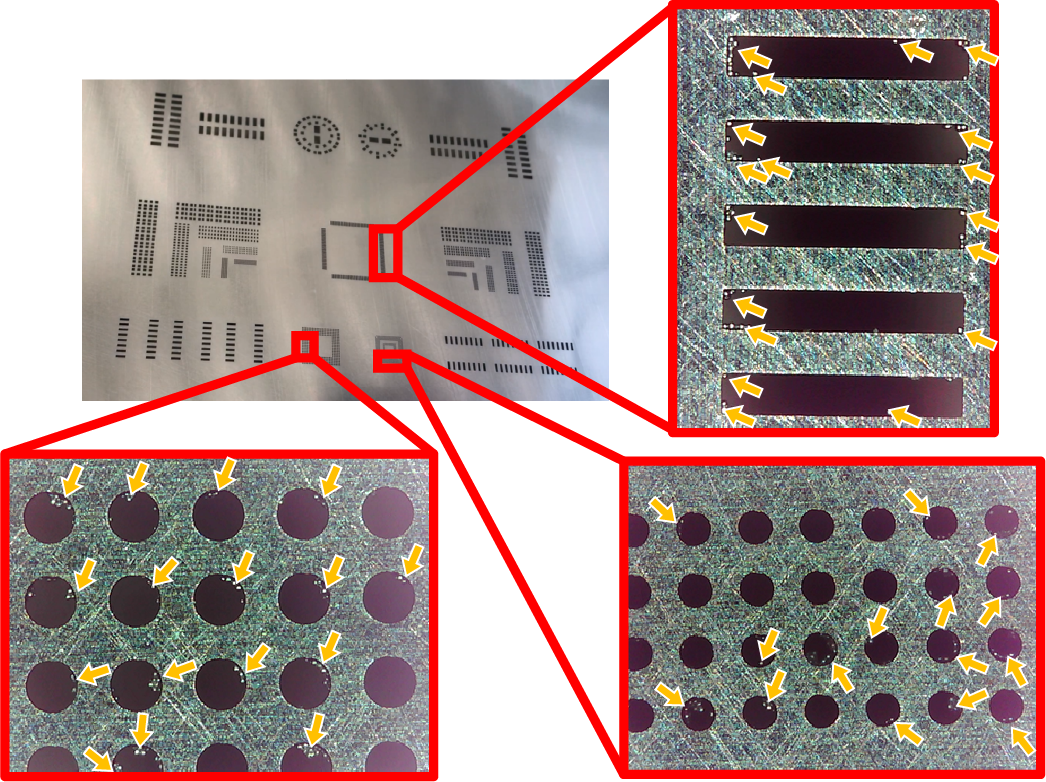

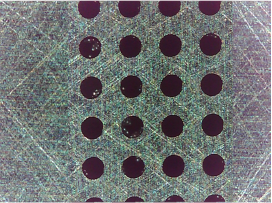

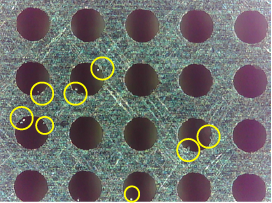

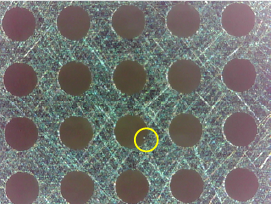

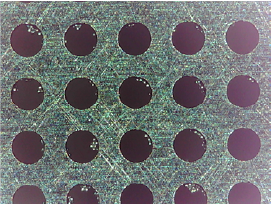

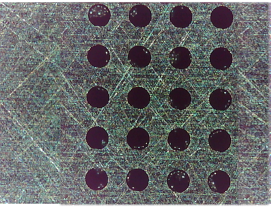

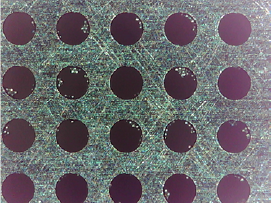

The white specks in the opening are solder particles. Let's see how well they can be cleaned using IPA, SMT stencil cleaning agents, and ultrasonic cleaning machines.

Following page explains the problems that can be caused by solder particles remaining in the openings.

|

Trouble solution

|

|---|

|

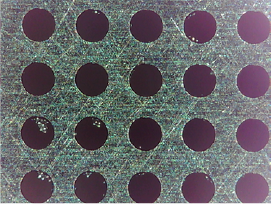

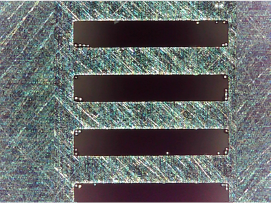

Wipe the front and back of the mask with a cloth soaked in IPA for about 3 minutes. Then finish by wiping it off with a dry cloth. |

|

|

|

|

|

|

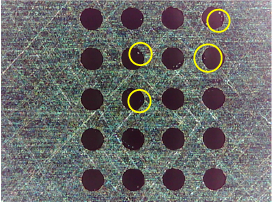

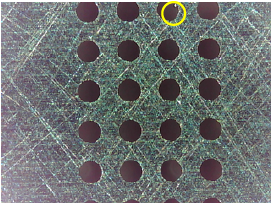

There are a lot of solder particles left in the area circled. This cannot be referred to as a successful cleaning...

|

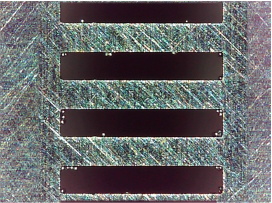

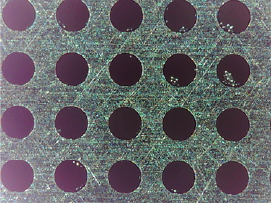

Let's try cleaning using the HA-4900 spray for cleaning SMT stencils. Spray the cleaning spray HA-4900 and then wipe it up with a cloth. Wipe it up and clean it for about 3 minutes in the same way as with IPA, and then finish by wiping it up with a dry cloth. |

|

|

|

|

|

|

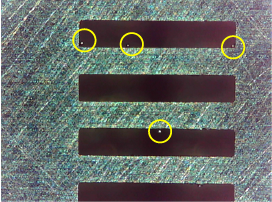

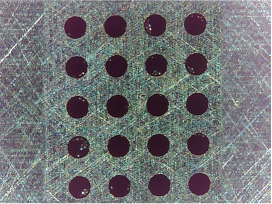

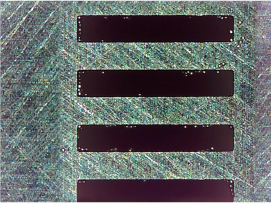

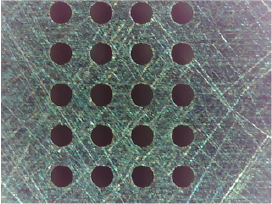

Compared to manual cleaning using IPA, the amount of solder particles remaining on the SMT stencil has been reduced. However, it is not yet perfect.

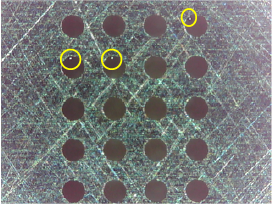

For stubborn paste and solder particles remaining in small apertures, we recommend cleaning with cleaning spray HA-4900 for SMT stencil , followed by use of a handy-type ultrasonic cleaner (SAWA CORPORATION SC-500H)!

|

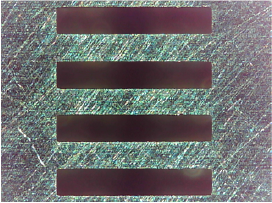

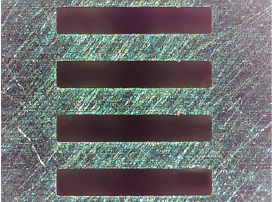

After spraying the cleaner, press the SC-500H cleaning head against the opening of the SMT stencil. (Hold it in place for about 5 seconds per location.) |

|

|

|

|

|

|

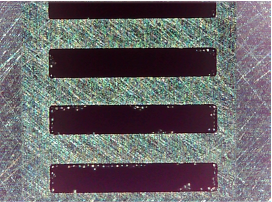

The solder particles were almost completely removed.

|

Lay the attached bat and soft pad. Place the metal mask on the soft pad and apply the cleaning agent. Ultrasonic waves are emitted only while the button on the side of the cleaning head is pressed (the green light will turn on). The cleaning agent, SMT stencil and solder particles vibrate due to the ultrasonic waves, and the solder particles detach from the SMT stencil. The detached solder particles become entangled in the soft pad and do not re-attach to the SMT stencil. |

|

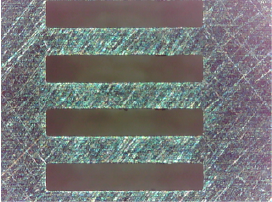

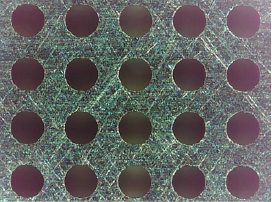

Even a handy ultrasonic cleaner can clean quite well, but if there are many SMT stencils, it takes time and manpower to clean each one. In addition, there may be differences in the cleaning performance depending on the operator. If you have a large number of SMT stencils to clean, or if you want to ensure consistent cleaning quality, we recommend an automatic cleaning machine. The SAWA ECO BRID SC-AH100-LV (made by SAWA CORPORATION), which is also sold by KAKEN TECH, realizes Here we will introduce the actual cleaning mechanism and cleaning power. |

|

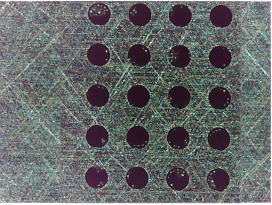

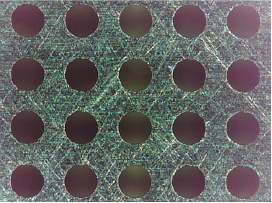

The ultrasonic cleaning head and vacuum drying nozzle are built into a single unit! The front and back of the SMT stencil are clamped in place, and the cleaning and drying processes are carried out simultaneously. Compared to conventional machines, the time from cleaning to drying can be greatly reduced (as little as 6 minutes). |

|

|

|

|

|

|

There are no solder particles left, and it has been cleaned thoroughly.

IPA is not good enough! | |

|

Are you cleaning your SMT stencil using IPA? IPA has a low cleaning power, and any solder particles that are not removed completely may cause quality defects in later processes! In the future, it is expected that cleaning solder paste and solder particles using IPA will become even more difficult as the apertures become narrower. Furthermore, because IPA is a flammable solvent, it is costly and time-consuming to comply with regulations regarding its storage and use. |

Use a cleaning agent for SMT stencils. | |

|

First, let's change to a cleaning agent for SMT stencils from IPA to improve the cleaning performance! A handy ultrasonic cleaner is also effective for stubborn dirt and difficult-to-remove solder particles. |

Automated machines help reduce labor and stabilize quality. | |

|

If you have a large number of SMT stencils or if your stencils have smaller apertures, we recommend introducing an automatic cleaning machine (SAWA CLEAN series). Introducing an automatic cleaning machine has the advantages of <reducing the time and manpower required for cleaning> + <ensuring consistent cleaning quality>. |

Please watch the video we made of the content on this page!

|

Products information

|

|---|---|

|

Trouble solution

|

| Please be as specific as possible in your inquiry. Depending on the contents of your inquiry, it may take some time for us to reply to you. If you need product documentation (SDS/safety data sheets, TDS, instruction manuals, etc.), please contact us via “Request for SDS and other product documentation” ※Sales message through the inquiry form are strictly prohibited. |

KAKEN TECH, MICROCLEANER, MICROCLEAN&MARKLESS and MARKLESS are trademarks of KAKEN TECH CO., LTD. in PRC.

KAKEN TECH is a trademark of KAKEN TECH CO., LTD. in the U.S..