- Company

- Products

- Technical report

- Indusrial cleaning

- Micro Joining and Assembly Technology

- Ultrasonic technology

- Trouble solution

- Cleaning

- Removing

- Attaching

- PCB Columns

Particles refer to particulate foreign matter that is mostly insoluble in cleaning agents and water, ranging from airborne dust to metal and resin powder generated by cutting of parts and abrasion of manufacturing equipment, as well as skin fragments and sebum derived from the human body. In addition, despite strict dust control using clean rooms at production sites for electronic devices and other products to ensure product quality, the sources of particles are diverse and difficult to eliminate from the very foundation.

If particles adhered during the manufacturing process of electronic devices are not sufficiently removed and remain on the component parts, they may scatter inside the electronic device due to vibration or shock during the assembly process or when the device is operated as a product. Particularly in camera modules and sensors, these particles contaminate light-receiving elements such as CCD (Charge Coupled Device) and CMOS (Complementary Metal Oxide Semiconductor) image sensors and lenses from the inside.This can have a serious impact on product quality by degrading image processing accuracy and causing false detections.It is important to establish a process to remove the causes of such defects in the manufacturing process and to improve the quality of the final product by using an appropriate method to remove particles.

This paper introduces the cleaning agent “ MICROCLEAN FPS” and the cleaning equipment “MICROCLEANER® FPS” as a newly developed environmentally friendly system dedicated to particle removal by applying the cleaning agent formulation design and cleaning process design technologies that we have developed over many years in the flux cleaning field.

Fluorinated cleaning agents such as HFE (Hydrofluoroether) and HFC (Hydrofluorocarbon), water-based cleaning agents containing surfactants and alkaline components, and pure water have been widely used as cleaning agents for particles in general. Fluorinated cleaning agents are nonflammable liquids with no risk of ignition or explosion under normal conditions of use, and have excellent drying properties due to their lower specific heat and latent heat of evaporation compared to water, and have little effect on various components1). On the other hand, HFE and HFC have no chlorine in their molecules and have no structure that has affinity for lipids, so they lack the ability to dissolve fats and oils, making it difficult to completely remove particles that are firmly adhered to the product, such as protein stains that have been deposited on the product due to thermal history. In addition, as an environmental problem, fluorinated organic compounds (PFAS) contained in fluorinated cleaning agents are not easily decomposed in nature, and there are concerns about their persistence in the environment and bioaccumulation. Aqueous cleaning agents and pure water have been widely used for particle cleaning applications because they are inexpensive and readily available, and because a combination of cleaning methods can be selected according to the application, including ultrasonic, spray/shower, and jet cleaning. On the other hand, the rinsing process consumes large amounts of deionized water and requires large wastewater treatment facilities. Quality issues include increased dielectric loss in electronic circuits due to residual surfactants in aqueous cleaning agents, and corrosion of metal parts due to strong alkaline components added as active ingredients, which reduces the reliability of electronic devices.

Cleaning agents containing organic solvent components such as hydrocarbons and glycol ethers exhibit excellent cleaning performance against a wide range of stains, including not only protein stains but also inorganic and organic particles such as metal and resin powder, depending on the choice of molecular structure. On the other hand, most of these components fall under the category of volatile organic compounds (VOCs), and efforts to reduce their emission have been intensified year after year due to concerns about air pollution and human health effects.

In view of this situation, we have developed a particle removal system that demonstrates high removal performance for a wide range of particles and solves the environmental issues faced by conventional cleaning systems.

Currently, we have two types of cleaning agents for particle removal: MICROCLEAN FPS-4712 (hereafter referred to as “FPS-4712”) and MICROCLEAN FPS-4700 (hereafter referred to as “FPS-4700”). FPS-4700 is a neutral type cleaning agent containing approximately 90% water, which further reduces the VOC content from FPS-4712 and has no effect on most metal and resin materials used in electronic devices due to its formulation design.

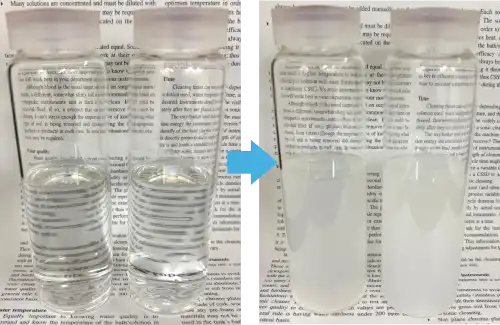

While both cleaning agents maintain a uniform transparency in appearance at room temperature, they separate into an oil phase and an aqueous phase with very different polarity at the temperature at which they are used for cleaning, and maintain a uniform cloudy emulsion state under agitation (Figure 1). Since it does not contain any non-volatile components such as surfactants, it can be cleaned and rinsed simultaneously in a single liquid operation that does not require a rinsing process. The formula is designed to lower the vapor pressure of the liquid compared to that of pure water, which also makes it easier to dry, and there is no risk of residual cleaning agent components remaining on the product surface, resulting in quality defects. In addition, the product does not contain any PFAS substances or any of the 100 major VOCs listed by the Japanese Ministry of the Environment, and does not fall under the Japanese Industrial Safety and Health Law (Organic Law), Japanese Fire Service Law, or any other related laws and regulations in Japan, making it highly environmentally compatible and safe to work with. Furthermore, in terms of the VOC regulations (limit value for volatile organic compound content in cleaning agents: GB38508-2020) enforced in China in 2020, FPS-4712 complies with semi-aqueous cleaning agents and FPS-4700 with low VOC content semi-aqueous cleaning agents, and can be used without problems in China (Table 1).

Figure 1: Comparison of the appearance of MICROCLEAN FPS before and after heating

FPS-4712 (left), FPS-4700 (right)

Table 1: MICROCLEAN FPS-4712/MICROCLEAN FPS-4700 General Properties

| Product# | FPS-4712 | FPS-4700 | |

|---|---|---|---|

| Appearance | Standing at RT | Colorless and transparent | Colorless and transparent |

| heating and stirring | Cloudy emulsion | Cloudy emulsion | |

| Specific gravity | 0.98 | 0.99 | |

| Surface tension mN/m(25℃) | 30 | 32 | |

| Boiling point ℃ | ≧100 | ≧100 | |

| Flash point ℃ | None | None | |

| Ozone Depletion Potential(ODP) | 0 | 0 | |

| China VOC Regulations (GB38508-2020) | Semi-aqueous | Low VOC Semi-aqueous | |

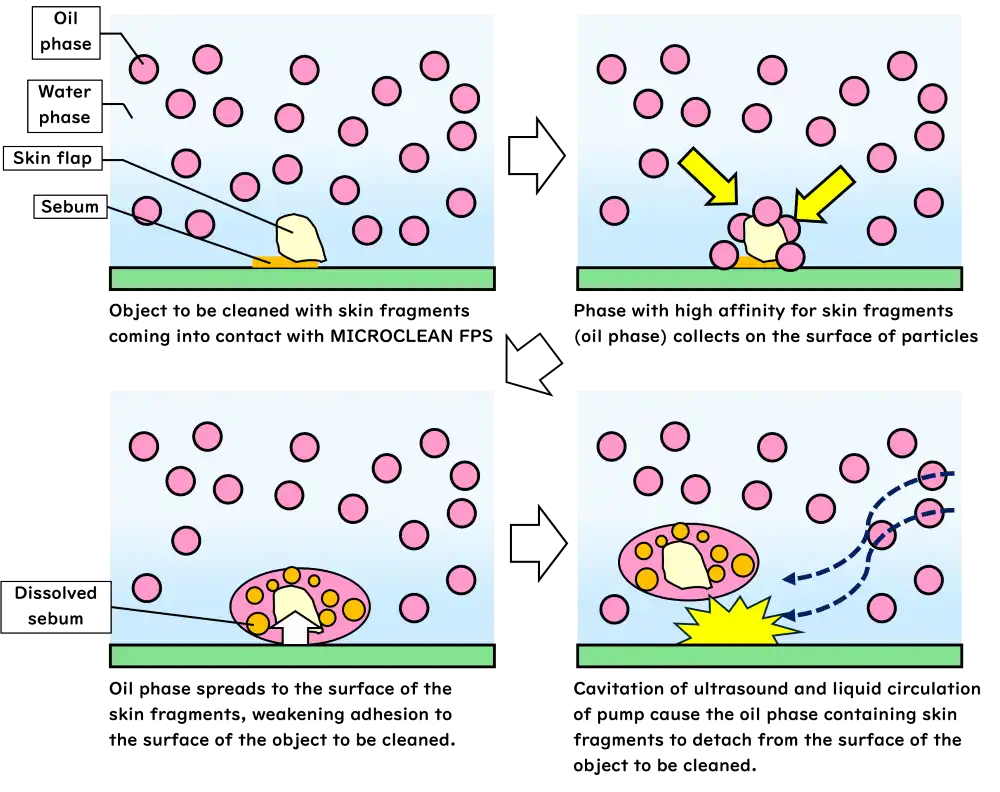

In the case of particles with diameters on the order of nm to μm, mutual attractive forces such as van der Waals forces, electrostatic attraction, and solid/liquid cross-linking forces act dominantly between the base material and the particles, resulting in relatively high adhesion, making removal difficult3). FPS-4712 and FPS-4700 are assumed to weaken the chemical and electrical adhesion of particles and promote their desorption and dispersion from the surface of the base material through the following mechanism (Figure 2).

Figure 2: Mechanism of MICROCLEAN FPS removal of organic particles (skin fragments + sebum)

| ① | The two phases (oil phase and water phase) with different polarities in the separated cleaning agents come into contact with the particle surface in an alternating sequence.In this case, the phase with the higher affinity preferentially spreads on the particle surface. |

|---|---|

| ② | The selective wetting and spreading phase penetrates the gap between the base metal and the particles and weakens the adhesion. |

| ③ | The other phase pulls them away from the surface of the base material and quickly disperses them in the liquid, combined with the effects of external actions such as ultrasonic cavitation and liquid circulation of the pump. |

Furthermore, FPS-4712 negatively charges each surface of the base material and particles due to the alkaline component in the cleaning agent, which promotes desorption and dispersion of particles by electrostatic repulsive force4).In addition, both cleaning agents have a structure in which the oil phase is uniformly dispersed in the water phase, which enhances the propagation of ultrasonic waves and maximizes the cavitation effect.

The synergistic effect of these cleaning agents allows them to remove any type of particles and demonstrate higher removal performance than fluorinated or water-based cleaning agents. In fact, test samples were prepared by simulating the adhesion of particles with different physical properties, and the removal performance of each cleaning agent was compared. As a result, as shown in Table 2, good removal performance was demonstrated for various types of particles.

Table 2: Particle Removal Comparison Evaluation Results

| Object to be cleaned | Before | FPS-4712 | FPS-4700 | Fluorinated | Water-based |

|---|---|---|---|---|---|

| Sebum + sebum fragments Average particle size: approx. 20um |

- |

◎ |

〇 |

△ |

〇1 |

| Sebum + talc Average particle size: approx. 0.5um |

- |

◎ |

〇 |

△ |

× |

| Alumina Average particle size: approx. 3um |

- |

◎ |

◎ |

◎ |

〇 |

Removal Efficiency Evaluation Criteria: ◎: 99% or higher / ○: 98–90% / ○1: 89–70% / △: 69–40% / ×: 39% or lower

Cleaning Conditions: Ultrasonic 45 kHz / 300 W, 50°C / 1-minute cleaning

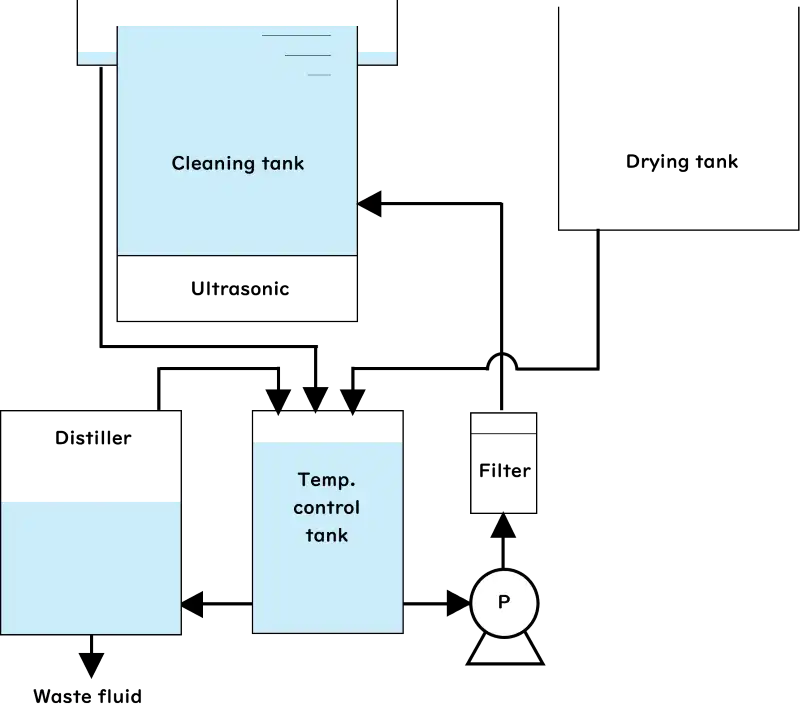

The MICROCLEANER® FPS is a dedicated cleaning equipment designed to maximize the performance of the MICROCLEANER FPS.The MICROCLEAN FPS is designed to be operated as a single component without rinsing, and is based on a two-tank configuration consisting of a cleaning tank and a drying tank, as well as an ultrasonic cleaning system (Figure. 3).

Figure 3. Model diagram of MICROCLEANER ® FPS

In particle cleaning applications, there is a correlation between the particle size to be removed and the suitable ultrasonic frequency5). Frequencies below 40 kHz are effective in removing particles with relatively large diameters of several tens of micrometers or larger that are firmly adhered to the substrate due to the strong impact force caused by the cavitation effect. On the other hand, as the frequency increases, the cleaning action is dominated by the straight-line flow generated by molecular acceleration motion, and the cleaning proceeds by the force of the cleaning agent's constituent molecules impacting the target object, making it suitable for removing particles smaller than a few microns. However, simply installing an ultrasonic device in the cleaning tank that matches the particle size of the target object does not provide sufficient cleaning effect, and it is necessary to take measures against any external factors that may interfere with the propagation of ultrasonic waves. MICROCLEANER® FPS significantly reduces bubbles and uneven flow velocity that inhibit propagation of ultrasonic waves by achieving uniform and gentle liquid flow (laminar flow) in one direction, and maintains uniform sound pressure in the tank.

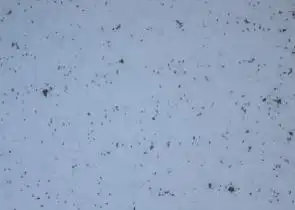

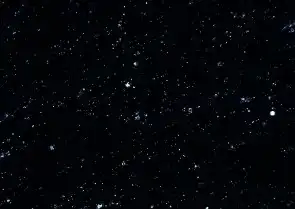

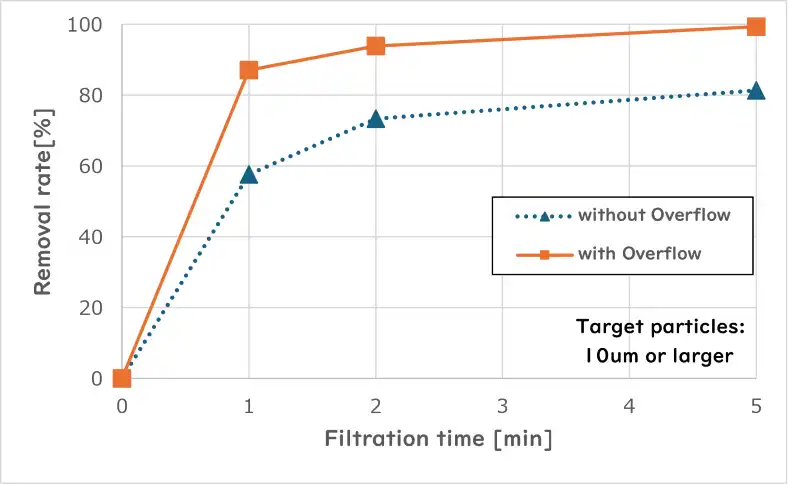

To ensure cleaning quality, it is most important to control the amount of particles in the liquid and prevent their re-deposition on the cleaned object. In the MICROCLEANER® FPS, particles brought into the tank are quickly discharged out of the tank by cascading overflow liquid circulation. The liquid circulation path is equipped with a filter selected based on the particle size to be removed, and the total filtration method enables efficient removal of particles in the liquid in a short time (Figure 4). As a result, as shown in Figure 5, nearly 100% of particles are removed from the cleaning tank after 5 minutes of filtration, and there is no concern about particles reattaching to products. Some of the extremely fine particles and contaminants soluble in the cleaning agent that cannot be removed by the filter are concentrated in a continuous distillation and recycling device that is built in as standard equipment, and discharged outside the system to maintain the cleaning tank in a state close to that of fresh liquid at all times. Products cleaned with this system have achieved excellent results in various analysis methods, such as visual inspection and liquid particle counter methods.

Figure 4: MICROCLEANER ® FPS liquid circulation flow diagram

Figure 5: Comparison of liquid circulation system and particle removal rate in a tank

We are confident that MICROCLEANER® FPS, the dedicated environmentally friendly particle removal system introduced in this paper, will help our customers solves various problems faced by fluorinated and water-based cleaning agent systems, such as restrictions on applicable stains, environmental impact, drying, and component effects.

In addition to flux cleaning, we will continue our research and development in particle cleaning to meet our customers' needs and expectations, and contribute to the manufacturing industry by providing higher value-added products to the market.

【Source】

Industrial Cleaning, May 31, 2025, No. 35 (Japan Industrial Cleaning Council)

| Please be as specific as possible in your inquiry. Depending on the contents of your inquiry, it may take some time for us to reply to you. If you need product documentation (SDS/safety data sheets, TDS, instruction manuals, etc.), please contact us via “Request for SDS and other product documentation” ※Sales message through the inquiry form are strictly prohibited. |

KAKEN TECH, MICROCLEANER, MICROCLEAN&MARKLESS and MARKLESS are trademarks of KAKEN TECH CO., LTD. in PRC.

KAKEN TECH is a trademark of KAKEN TECH CO., LTD. in the U.S..