- Company

- Products

- Technical report

- Indusrial cleaning

- Micro Joining and Assembly Technology

- Ultrasonic technology

- Trouble solution

- Cleaning

- Removing

- Attaching

- PCB Columns

| Merit | Low temp. curing, low resistivity |  |

|---|---|---|

| Binder | Epoxy resin | |

| Curing condition | 100℃×60min | |

| Specific resistivity | 3×10-4Ω・cm | |

| Viscosity(@25℃ 5rpm) | 30Pa・S | |

| Pot life(@25℃) | 25hrs | |

| Storage condition | below-10℃ | |

| Container | 10g/5cc syringe |

|

■ Camera modules ■ Wearable devices such as wireless earphones ■ Internal electrodes for sensors ■ Component mounting on film devices |

|---|

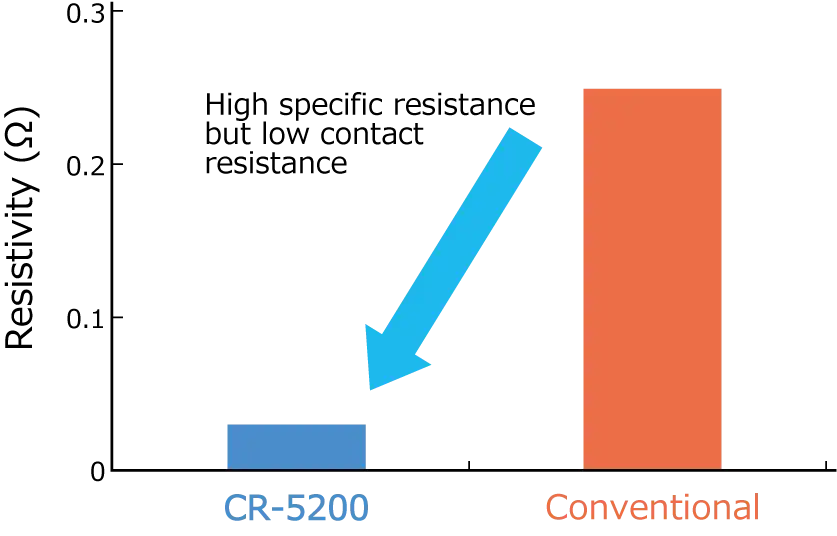

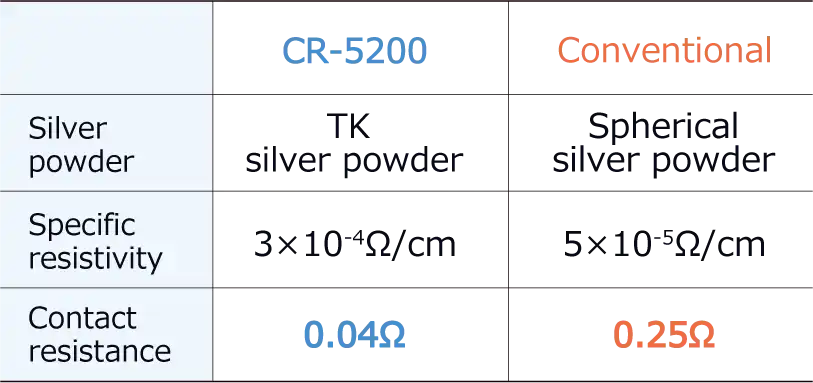

| Unlike solder, conductive adhesives have contact resistance at the interface of the connection. Even if the specific resistance (resistance of the adhesive itself) is low, if the contact resistance is high, the resistance of the entire circuit will increase. TK PASTE CR-5200 has extremely good conductive performance because the contact resistance is greatly reduced by the effect of specially shaped TK silver powder. | |

Contact resistance to SUS 316L |

|

|---|---|

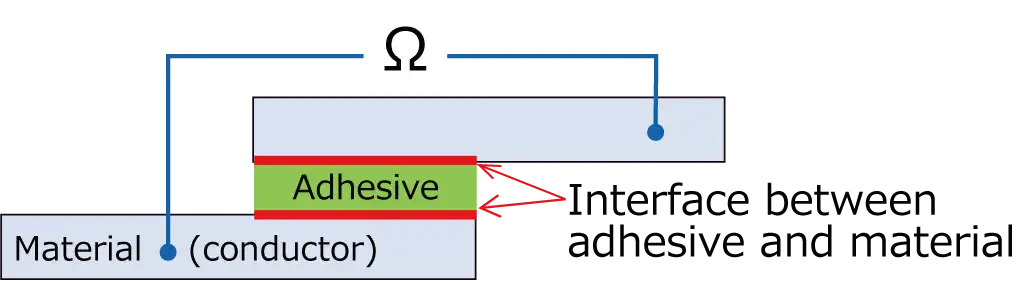

| Resistance present at the interface between the adhesive and the component. The above graph is the result of bonding a SUS316L plate with each conductive adhesive as shown in the photo on the right and measuring the resistance. Stainless steel in particular has a passive film on its surface, which deteriorates contact resistance, but CR-5200 has good conductivity. |

|

|---|---|

|

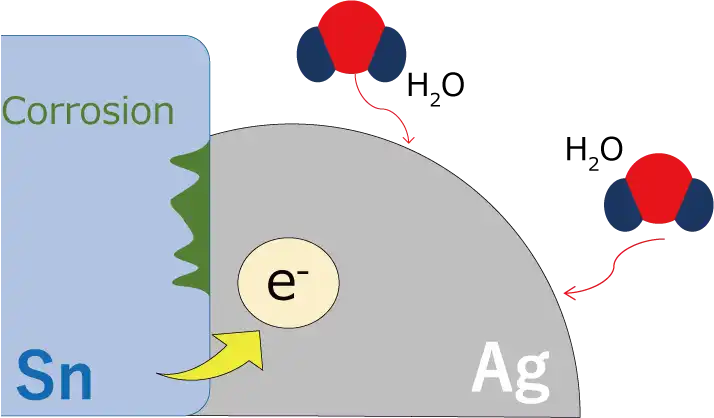

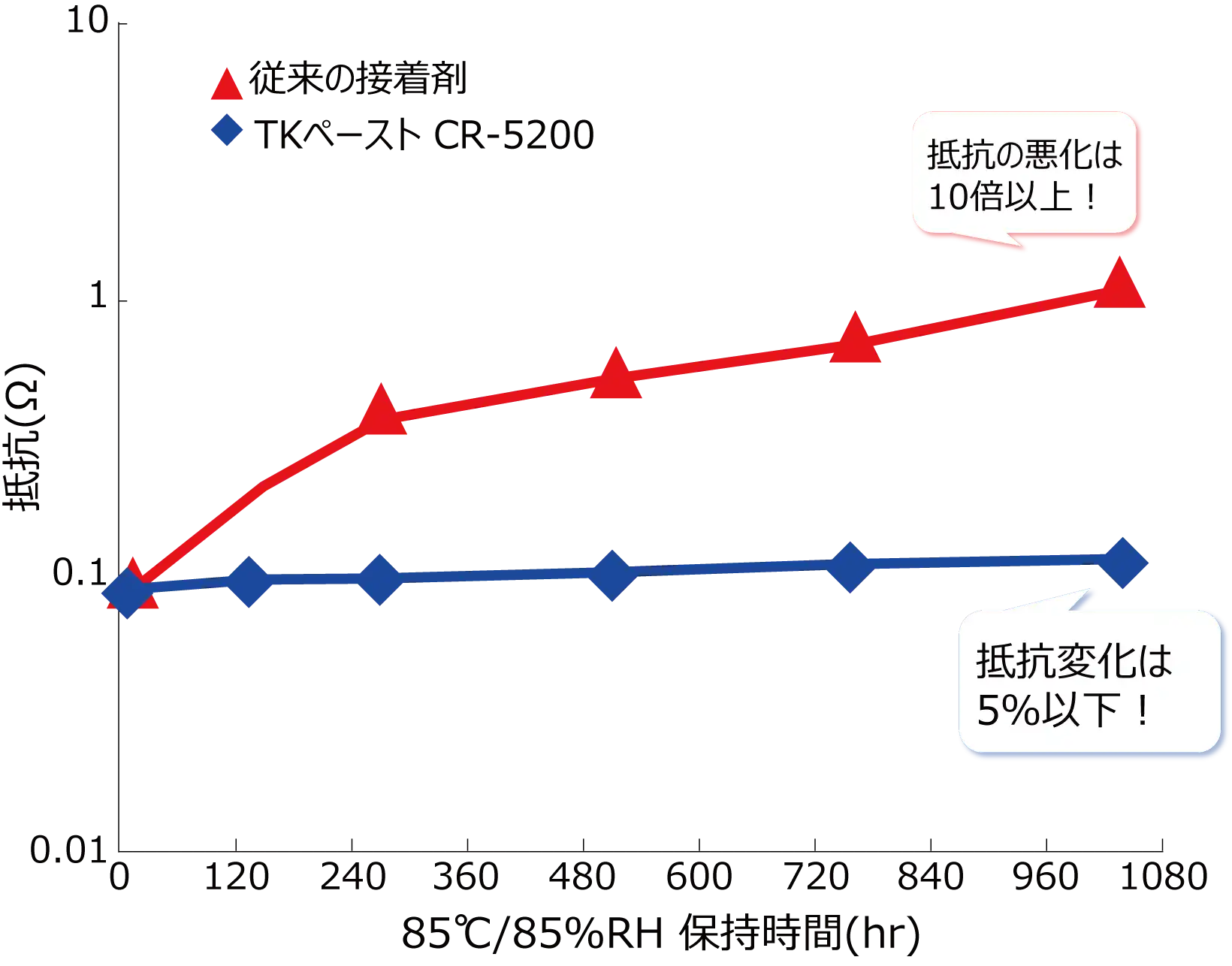

| When dissimilar metals come into contact with each other in a humid environment, metal corrosion occurs due to the transfer of electrons (known as potentiometric corrosion or galvanic corrosion). |  Corrosion due to contact with dissimilar metals (galvanic corrosion) |

|---|---|

| Conductive adhesives contain silver (Ag), and depending on the material to be bonded, conductivity and strength may deteriorate due to metal corrosion when subjected to high temperature and high humidity tests. In particular, tin (Sn) is commonly used for soldering to terminals of electronic components. However, tin has a large potential difference with silver, making it a combination that is prone to metal corrosion, so it is essential to pay attention to this combination. | |

| TK PASTE CR-5200 prevents the progression of metal corrosion with specially shaped TK silver powder, and maintains good conductivity even in high temperature and high humidity tests over a long period of time. | |

|

|

|---|---|

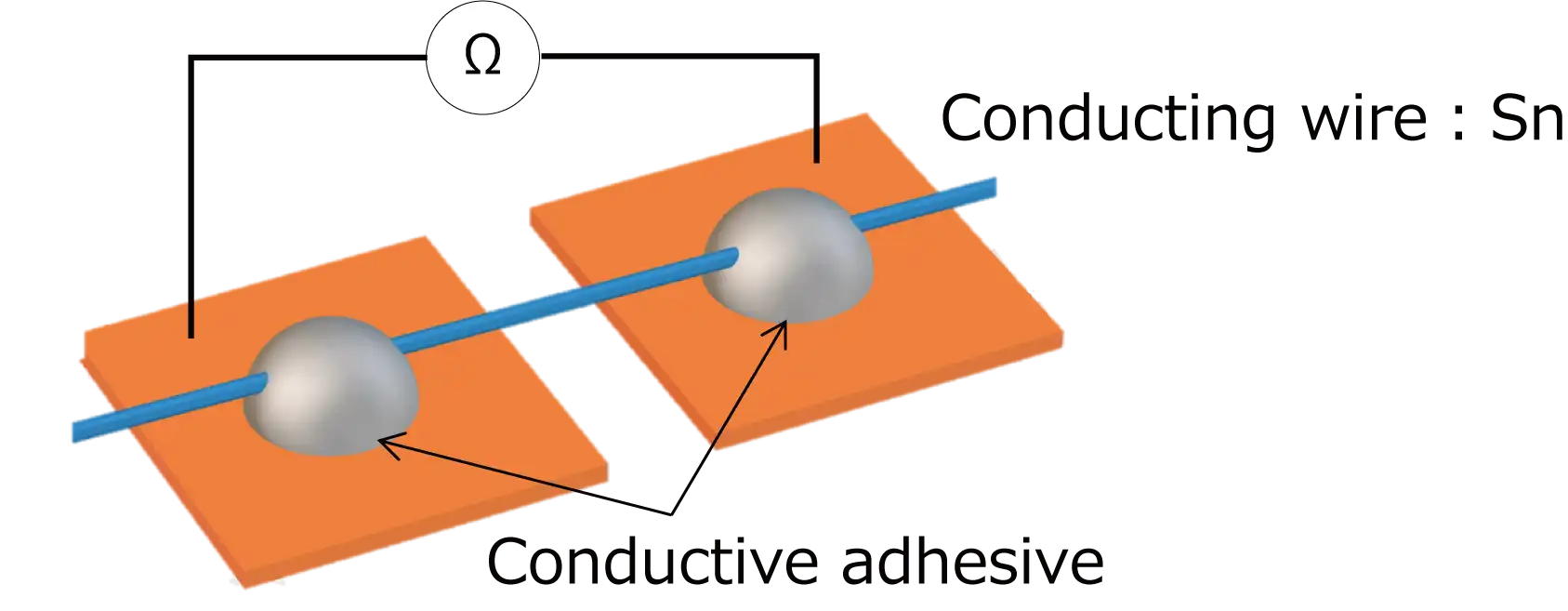

| Sn conductors were fixed on gold (Au) terminals with conductive adhesive, and the resistance was measured for each hour after being put into a high-temperature, high-humidity testing machine. |

| Please be as specific as possible in your inquiry. Depending on the contents of your inquiry, it may take some time for us to reply to you. If you need product documentation (SDS/safety data sheets, TDS, instruction manuals, etc.), please contact us via “Request for SDS and other product documentation” ※Sales message through the inquiry form are strictly prohibited. |

KAKEN TECH, MICROCLEANER, MICROCLEAN&MARKLESS and MARKLESS are trademarks of KAKEN TECH CO., LTD. in PRC.

KAKEN TECH is a trademark of KAKEN TECH CO., LTD. in the U.S..